|

I'm sending this guitar using FedEx who have given me more than a decade of reliable and safe shipping. I did read that it's wise however to protect contents with plastic if the weather is unusually wet (which it is) The whole thing is now sealed in plastic just in case.

|

Left: We are having some rainy wet weather here so although it's a remote risk, I wrapped the instrument in plastic for additional protection in transit. Right: The wrapped instrument has now been packed into a shipping box with a lot of additional padding and protection. I will now seal it up and weigh and measure! |

The waterproof package has now been packed in a shipping box with plenty of padding added. This should be a very safe instrument. It may be exposed to cold-ish temperatures but should not affect the instrument inside. It will be delivered straight to my customer's door.

|

|

Getting the instrument settled securely in its Protec case. Should be safe for its travels. I will be packing the actual shipping box very carefully!

|

Left: Getting ready to ship - firstly, strings are loosened a bit to minimize travel stress on neck. I used packing to fill any spaces that could allow internal movement. Right: Protec case is sealed up and ready to travel. The accessories are packed in the front pocket. This case is very good protection for the full instrument! |

The guitar is now securely contained in its Protec case. I will now collect all my other shipping supplies and get the case safely in its shipping box for its upcoming journey.

|

|

Very cool and unusual headstock based on my customer's concept. Everything on this guitar is different which is a good thing!!!.

|

Left: I'm posting a few photos of the finished monster so that I have them here on the site. This is the headstock area which is based on customer design. Right: Quick photo here of the fanned fret fingerboard using two different woods and incorporating Morse Code inlay fret markers and LED powered side dots. |

The fingerboard is very unique the curly maple is a nice feature!

|

|

Removed the excess filler from the little voids I filled and I will now add a little finish to the insert before I attach it to the back of the neck.

|

Left: OK - filled the voids and will now it it with a light coat of sealer/varnish. After that it gets installed and becomes part of the guitar and I think we're done. Right: The very unique nameplate is now installed in the back of the headstock. I think we can call this guitar pretty much complete now. Looks very nice. |

The nameplate is now part of the headstock of the guitar. It's raised up just a little bit from the headstock surface which gived it a nice 3D effect. Will do a final tune up/test tomorrow.

|

|

I bought a few more inlay colors and we decided that we would do gold in the nameplate. The color is beautiful so it should yield good results. This will take all night to fully cure but should have some images to share tomorrow!.

|

Left: Last minute change - we're going for GOLD in the nameplate so I have mixed up the formula and filled the engraved areas in the piece of mahogany. Need to wait till it cures. Right: This is the insert with the excess filler scraped off. I have a few small (and expected) air pocket voids which I will now fill to finish. |

I scraped the extra filler off the top surface this morning and this is the insert about 90% cleaned up. I need to add a little filler in a few spots that were caused by inevitable small air pockts. Once I do that I will do a final scrape and sand and add a wood finish which will increase the contrast and colors even more!!!!.

|

|

Machining the recess using very small cuts to avoid compromising the finish. I will post a photo of the finished results soon.

|

Left: Busy machining the recess in the back of the headstock. Taking a lot of care to avoid chipping the existing finish so only taking very small cuts! Right: Recess has been machined without any collateral damage and the insert fits in there nicely. I need to get the filler mixed and aadded into the engraved areas now. |

The recess has been successfully machined into the back of the headstock and I am now ready to fill the insert with the powder mix and get that part finished.

|

|

This is the filler I had in mind. It's white pearlescent which should create a nice silvery inlay similar the artwork on the back of the neck.

|

Left: While other things are going on I looked out my Silver/White pearlescent pigment powder which looks like it will be a good color match to the Crop Circle artwork on the back of the neck!!! Right: OK the guitar is now up on the CNC - I HATE machining anything on a finished instrument so I am being turbo-careful. Stay tuned!!! |

In order to accurately cut the recess for the insert I HAVE to set this guitar up on the CNC. Not easy clamping a finished piece of artwork on the machine. I'm being VERY careful to avoid any clamping issues and will be relieved when it's done!.

|

|

I now have the insert blank ready for engraving. I will have it slightly raised from the back headstock surface to make it a feature - also aware that there are string retainer screws behind it although they should not be aan issue. Next is laser engraving.

|

Left: The insert is ready for laser. I'm planning to have it just slightly proud of the headstock surface when it's installed. Should look good that way! Right: Just finished on the laser and I am happy with the quality of the engraving. Ebony is hard stuff but I was able to get a good clean result and can now move to the next step. |

It was a tricky set up and I had to be very careful with alignment of the artwork and selectingthe best power settings but the end result is very nice. I'll probably fine sand it and then work on getting the filler mixed, embedded and set.

|

|

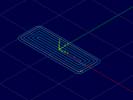

Got a couple of quick programs written. First one will complete the machining of the ebony blank piece. The second one will cut out a matching recess on the back of the headstock.

|

Left: Now writing a couple of programs - first one is to cut out the Ebony blank, the other is to cut a recess in the back of the headstock. Right: Got the perimeter of the logo insert machined and I will now sand it to finished thickness and get it ready for engraving on the laser. Also will set up CNC to cut the recess in the headstock! |

Going as fast as time permits - ran the program on the CNC for the insert outer perimeter which I will now set up on the laser to engrave.

|

|

We are adding a Watson Guitars plate on the back of the headstock - I'm currently working on this and will have real photos of the addition very soon!.

|

Left: Last minute addition before I ship - we are going to add a plate on the back of the headstock to identify this guitar as a Watson! This is an artist impression but will have real photos soon! Right: I machined a piece of Ebony close to the required thickness. Will now cut and drum sand it to get it ready for the laser engrave. |

Preparing a piece of nice dense Ebony for the nameplate. Will update as I go through the machining, sanding and engraving processes.

|

|

Guitar is ready to make its journey so I'm being very careful about making sure it can tolerate the bumps and changing temperatures on its journey to the customer.

|

Left: Busy packing everything! The case is very protective of the instrument but I put a few pieces of extra padding in there just in case! Right: Guitar and associated parts are now safely secured inside the Protec case and my next task is to get it carefully fitted into the shipping box and get the whole thing weighed and measured. |

Instrument now sealed up in its Protec case and I am now working on getting it boxed with plent of protective packing around it.

|

|

Did a good long list of final adjustments and I think it's ready for some final photos and then careful packing for its journey to my customer.

|

Left: I'm now ready to get this instrument packed and prepped for shipping. I'm trying to get some good glamor shots of it before I box it up! Right: Quick shot of the back of the guitar with the crop circles and various inlay areas. This one was not just a guitar but an art project as well!! Will post a couple more pics. |

Back of the instrument is very unusual. Have a lot of personalized inlay work on there for my customer.

|

|

Replaced the 9v batteries with new ones although it doesn't really use much power at all. Did a bumper to bumper check to make sure it was ready to ship. Now I have to get it safely packaged in a shipping box!

|

Left: Got new 9v batteries installed, also selected custom strap buttons and checked everything on the instrument. I'm going to take some glamor photos and then get it packed up! Right: We've been under possible fire evacuation and now enduring power cuts so I'm catching up on final adjustments! More pics coming! |

Recent local wildfires have cause the power supply companies to shut down neighborhood power so it's been a bit crazy trying to get what's needed done in daylight without electricity!!! Looking good though!

|

|

My most important remaining tasks are to make sure we have new batteries installed, that nut, neck are set for comfortable playing, and all being well I will need to safely pack the instrument and case in a strong well-padded box. Once that's done I have to weigh and measure it and get a quote from FedEx to transport it to its destination!!

|

Left: Final details, some truss rod adjustment, checking 9v batteries, gathering up all the adjustment tools & keys, making sure everything functions electronically. Right: Final tweaks on the truss rod and the bridge adjustments and I will tune everything back up to pitch and test things out. I will then get everything packed up!!!! |

I de-tuned to adjust truss rod and make a couple of other final adjustments. Will get it all tuned back up and see how it all performs. All being well I can get it packed up. Will de-tune a little for transport purposes probably!

|

|

Almost done with this beautiful guitar, just getting the strings back on for final testing!

|

Left: Frets have been leveled and polished up and strings and truss rod cover are back on. I'm now tensioning strings back up to required pitch and doing some testing to make sure action is good. Right: This guitar has some really unique stuff on it - I added a matching wood top to the 3-way pickup switch to make it even more custom! |

I added a custom top to the 3-way switch using the same wood as in the pickup inlays, made it myself with wood I had in my shop. Quite a tricky job when you don't have a little lathe to work with, but end result looks very good! I tried finding something on the internet but the quality wasn't great and I had to make it fit a 6-23 thread, not an 8-32 thread.

|

|

I took the strings off, used the truss rod to adjust the unstrung neck totally straight - then worked on the fret leveling to make sure all frets are on an even plane. With that done I will re-assemble everything and re-test playabiliy!

|

Left: Time for final fret leveling and fingerbord cleanup after which I will re-assemble with the strings and test the final truss rod and nut slot settings! Right: Did some minor fret leveling (didn't need much) so that we are ready to re-string the guitar, plus a clean and conditioner application on the fingerboard. |

I did a fret level to make sure there were no high spots and reconditioned the fingerboard so that I could get the strings back on the instrument!

|

|

Cutting the string slots in the nut to their final depths.

|

Left: I'm working on the finer details of the nut slot depths for the strings. Once they are all finalized I will make adjustments at the bridge end. Right: Working on the fine details of nut slot depth, fret leveling and truss rod adjustment. As soon as I finish that I'll replace the truss rod cover do some more testing! |

Nut slots are tricky because you can't go too deep or you'll mess things up - I'm adjusting a few thousandths at a time until everything is set right. Smaller strings can be closer to the frets than larger strings because the bigger strings have a bigger resonant amplitude - they vibrate more up and down near the nut!

|

|

I re-assembled all of the tuners and got them installed back on the guitar. One more task out of the way.

|

Left: I modified all of the tuners so that I could get a little more linear travel out of them and got them installed back on the guitar. Was able to achieve pitch requirements! Right: I'm working on the finer setup adjustments - string height, nut slots, truss rod adjustment, fret level just to make sure playability is comfortable. |

Working on the general setup and playability of the guitar.

|

|

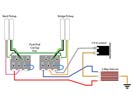

After some careful planning we were able to add the 3-way pickup selection into the circuit that incorporated the coil tapping features. Seems to test just fine so moving on!.

|

Left: Got the internal wiring done to include the 3-way toggle switch for pickup selection. We were able to maintain wiring for the coil splitting in same circuit. Right: One rather tricky thing I had to do was increase the travel of the tuning saddles by removing a little material from the back end of the insert! It seems to work though! |

Because of the unique tuning requirements for this guitar I had to give the tuners a little more linear travel by grinding off some of the saddle material at the back of each unit. After dong this I was able to achieve the required string pitches.

|

|

Another delicate job done - you have to be pretty careful with the finish when drilling through in situations like this!

|

Left: I established a hole and got the on/off switch for the LED lights installed in the body. I'm going to try and make a slightly custom end for the 3-way switch!! Right: After some discussion with my electronics guru we established a wiring plan that will allow the 3-way selector switch to work along with the coil tapping pots! |

This is the updated wiring digram that wil allow us to add the 3-way pickup selector to the existing circuit we currently are using.

|

|

Re-sizing the hole to accomodate the pickup selector switch. Next I will install a flush on/off button for the LEDs.

|

Left: I'm busy changing the LED switch to a 3 way pickup seletor switch which requires working on the hole size and recess depth. Also adding a low profile LED switch. Right: I had to get the guitar up on the CNC to machine out a couple of areas of relief in the control cavity since we are moving/adding switches! |

I have to do some minor machining in the control cavity to make the new switches fit properly - being very careful on handling the guitar!!

|

|

I have to do some minor machining in the control cavity to make the new switches fit properly - being very careful on handling the guitar!!.

|

Left: I have parts on the way to allow me to convert the existing LED on/off switch to a 3-way pickup selector and re-assign the LED on/off elsewhere on guitar body. Stay tuned!! Right: I received the 3-way switch and the switch unit for the LED on/off circuitry so I am going to get started on making the electronic changes!! |

The electronic hardware I needed has come in so I am going to get started on making the conversions and moving things around. I don't think it will be a super hard job.

|

|

Working on the string heights both at the nut and at the bridge saddle area.

|

Left: Working on nut slots and several other adjustments to get the string heights set and make sure neck/frets are ready for playing. Will be done soon! Right: Last minute changes required - going to put a pickup selector switch where the LED switch is and move LED switch to another location. Will post updates on this very soon!!!!! |

We're going to replace the existing switch (currently for LEDs on/off) with a 3-position pickup selector switch. Looking at relocating the LED on/off with a discrete push/push button in one of these two locations.

|

|

Adjusting truss tod as I tension up the strings, then will finish up the string slots in the nut and get the bridge saddles adjusted for optimum playing comfort.

|

Left: With the strings back on I am now working on neck, nut and bridge saddles to achieve a nice comfortable playing set up. Knobs going on also! Right: Quick shot of the guitar with knobs on. I had to get the hole size on each just the right size to allow the knobs to press on comfortably! Finally got them just right! |

The holes in the knobs needed to be very carefully sized so that they press onto the pot shafts with just the right pressure. Not easy to do but nailed it!

|

|

Removed saddle from the tuner and have it up on the CNC to get machined a little bit wider so that it fits the string winding. Should be back on the instrument very soon!!

|

Left: I ended up holding the saddle of the ABM bridge in a vice on the CNC and using a very small end mill to carefilly machine the string clearance slot just a tiny bit wider. Right: I was able to cut the slot on the low saddle wider so that the string binding would fit in there. Re-assembled everything and now back to final adjustments. |

Looks like everything worked out fine. Low tuner is now able to accommodate the string binding on the heavier string.

|

|

We're good on knobs, I'm now putting on the real set of strings for this guitar and will be tuning it up to its specific pitches. I'll do some testing and physical adjustments and see what we end up with!!!!

|

Left: I'm getting the knobs polished so they look as awesome as possible, also putting strings on the guitar so that I can get the hardware set up!! Right: While putting the final strings on I discovered that the ABM saddle retainer was too narrow for the string winding on the string gage my customer wants. I can fix though :-) |

The bottom string is slightly bigger than a standard low E and the winding was just a tiny bit too thick to fit in the adddle slot of the AMB tuner - I will dis-assemble the tuner and fix - should not be a big task!

|

|

Not bad! I think these will work very well on the guitar. I still need to apply the appropriate amount of finishing compound but most of the hard work is now done!!!!

|

Left: Got the machined recesses filled! I neeed to deal with a couple of small areas that have voids but otherwise all good. I need to re-apply the finishing compound and then they should be ready to use! Right: This is just a quick pic to show the two knobs on the guitar - I still have to finally fit them but they are cool and different!!! |

Quick test fit on the two knobs, I forgot that on the front they match the fingerboard inlay colors and the inserts on the pickups. Also setting up strings, saddles, nut etc...

|

|

I will make the colors on the knobs match those if the inlays on the back of the guitar.

|

Left: Now getting everything mixed and ready to do the specific colored inlay areas on the tops of the knobs. They should look pretty cool when they are done and mounted onto the guitar! Right: I want to get the colors on the knobs to be as close as I can get to the colors on the back. I think it's pretty close, will update! |

Mixing reflective colors to match the inlay on the back of the guitar. Using the screw on knobs as guinea pigs!!.

|

|

Managed to get all four knobs engraved on the CNC. I will now get them sealed, filled and finished so that I can attach 2 of them to the instrument.

|

Left: Very careful and intricate job but I got all 4 knob tops machined on the CNC. I will do some cleanup and then apply some sealer. After that I will fill the artwork with color. Right: The knobs have been cleaned up and given a coat of sealer. They are now ready for the inlay material to be applied. Should end up looking nice!! |

Got the knobs sealed and now ready for filling the engraved recesses with the inlay material!.

|

|

I had to create an unusual way to lock down the tapered knobs so that I could still accurately set the engraced artwork on center. I'm taking a lot of care to make sure this works out right!

|

Left: I tried engraving the two pieces of artwork using the laser but it was hard to guarantee position, so I am defaulting to the CNC using a tiny .025" cutter! Right: Did a little test run before actually cutting the top of a knob - came out looking pretty good so moving on to the real parts! Wish me luck!! |

Just wanted to see if the artwork looked ok before I committed to an actual knob. Looks like it should work fine so moving on.

|

|

These are still rough and have not yet been sanded and plished but glad they are done so far. Nexrt step is to get them sanded smooth and cut the inlay art on the laser!!

|

Left: Drilling and tapping the sides of the regular knobs just incase we need them. After sanding they will all be ready now to get the fancy artwork inlaid in the tops. Right: Time to get some strings on this instrument and get the bridge saddles, nut slots and overall action adjusted to a nice comfortable place. Almost there!!!! |

Right now I am using spare strings just to establish the locations for small indents in the bridge saddles. Once that's done I will put the REAL set of strings on and set up all the action related parameters.

|

|

I managed to get the inserts to fit all the way into the knob holes - I still have to reduce them in height to match the knobs but will have that done very soon and will then glue them in.

|

Left: I'm modifying the plastic inserts so that I can get them securely glued into the holes in the knobs. Once that glue has set I will sand the knobs and apply finishing!! Right: Reduced the insert length to match the available depth in the knobs. Next op will be to sand them all nice and smooth then set up for artwork. |

These are the knobs with the set screws but I wanted to show them in place - this is bare wood so when they have finish applied they will be darker, and blend with the same colors on the guitar itself!.

|

|

Machined the backs of the first pair of knobs and got them separated from the main blick and sanded down to finished height. Now have to repeat that with the other two.

|

Left: I got the first two machined on the bottoms - they just need to be cleaned up and then I have to engrave the tops!!!! The second two now need to go back on CNC. Right: Knobs are now drilled, recessed and machined to finished height. I'll sand/polish them next and then get then probably insert the sleeves on two of them. |

After some more machining I have these knobs in a more complete stage. They need sanded and two of them need the plastic sleeves inserted in the larger holes I machined.

|

|

Goal here is to machine holes, clearance and overall knob height in one setting. I'm going to make two knobs for each position - one with insert and one with set screw since I don't know which will perform better in the pots which operate as push/pull.

|

Left: I am machining the under sides of each of the knobs so that I can achieve the best overall height, hole size and relief on the bottom areas. Right: Working on the bottoms of the two sets of knobs. tricky stuff but I should be able to yield two successful sets. Next operation is to create counterbores and a recess in one of them. |

Not easy making knobs without a lathe because you have to work on both sides of these to make them work and it all has to be concentric.

|

|

Tricky work to make sure these things come out right. I have some more gluing, drilling and machining to do so will keep posting progress.

|

Left: I'm carefully working on some knobs with my pre-glued wood. If all goes well it should give me a couple of useable options for the custom knobs. I will then use laser to engrave tops. Right: I have created knobs from the top side and I'm now figuring out a setup so that I can machine the recesses in the backs for inserts. |

Managed to get some knob blanks completed but now have to machine the back recesses and try to fit the inserts in at least one set. Inserts are a little tight but I think I can make them do their job, It's just all a little time consuming but will continue to post progress photos.

|

|

Doing the first cut on the laminated blank to create one of the custom knobs. Doing my best to make this work out on the CNC.

|

Left: Cutting the knob with the double maple layers - hopefully this will give me some good results. Right now it's just roughed out but more pics coming. Right: The knob looks pretty good - I need to find a good way to hold it to clean it up - this one was a test case so I will use it to experiment and resolve a few things.... |

So far so good but I need to find ways to hold it and allow me to clean up the base and if possible, open up the recess for the inserts.

|

|

I'm going to have to machine the under side of that knob first and use the center hole as a positioning reference so that I can perform the outer roughing and finishing. Slightly involved but I will get there!!.

|

Left: Last knob was ok but I need to machine them in a way that gives me a concentric hole for the pot shaft (or insert) so this drawing illustrates what I will have to do. Right: The press-on inserts were actually a little small and did not fit pot shafts. Was able to enlarge them a tiny bit to fit so will try this on the machined knobs. |

To be safe - if I can - I am going to make a set of knobs with the press-on inserts and a set with set screws. Just not sure of the predictability of the end result so playing it safe.

|

|

I cut a test knob to see what kind of finish I yielded. Decided to add a roughing cycle first so that the finish cut only takes of a small amount of material. That should help avoid surface discoloration due to heat generated and also improve machined finish.

|

Left: Test run on cutting knob shape was pretty good. I need to revise the program to rough and then finish the shape to improve finish and avoid burning. Right: I am trying a slightly larger knob using a roughing cut followed by a finishing cut. I'll clean this one up and see if it will work for the instrument. |

Trying to make the CNC mill be a lathe - I sould be able to get something nice out of this.

|

|

This material is ready to run in the CNC to create the two custom knobs.

|

Left: These are the blanks from which I am getting ready to machine the custom control knobs. I have a program written now which I will be testing! Right: Testing the program to cut a tapered wooden knob that will fit this guitar. If it works on spare wood I will go ahead and run it on the wood I laminated. Fingers crossed. |

I rarely need to run and 3-axis jobs but due to the fact that I do not have a lathe and I need to generate a tapered cylindrical shape for these knobs, this is the best way.

|

|

I have a couple of gluing projects going on to create the blanks for the two custom knobs on this guitar.

|

Left: Gluing some of the decorative laminates for one of the knobs right now. Working on a program to generate the taper and artwork for the two tops. Will update. Right: Just a quick update to say that I received the knob sleeves that I hope to use to allow the new knobs tp press on in place. Have to test them but will update! |

These plastic inserts are designed to allow knobs to be pressed onto the potentiometer posts so I am going to test them on the ones installed in the guitar and see if they might work.

|

|

I'm going to try to make the two knobs as close to this artwork as possible. Forst job will be creating a layered block from which I can cut the shapes.

|

Left: This is a drawing of the plan for the two knobs on the instrument. I don't want to make them too tapered since they need to operate the push-pull pots. Right: I sawed up and sanded the material that I will be using to create the custom knobs on this guitar. I will post more pics of the progress on this very soon. |

I sawed up the wood for the creation of the two custom knobs. I also got all the pieces sanded flat so that I have good clean surfaces to work with. I will now glue them together to create the blanks for the two individual knobs.

|

|

I'm working on the bridge saddles and at the same time planning the machhining process to create the custom knobs!.

|

Left: I am replacing these chrome knobs with custom machined and engraved/inlaid ones. The wood on the right will work well and allow me to experiment to get them done correctly! Right: I got the holes for the recessed strap locks cut into the body today - not an easy job as you do not want to chip the finish! Moving on.... |

I got the two recesses for the strap lock hardware cut into the body - glad that is done.

|

|

To keep everything streamlined we're looking for the best way to make the strap lock components connected to the guitar, flush as possible with the mounting surface. I think we have a good option to make this happen. Picture shows a Dunlop flushmount as an example. Also we are going to fit the guitar with custom wooden knobs rather than the chrome finish. More on that very soon.

|

Left: Couple of modifications in the works - want to make the straplocks on the body flush, plus we're going to manufacture custom wooden knobs rather than standard chrome. Right: We agreed on a black insert and a chrome strap assembly. I will work on the two strap locations to create suitable counterbores for these. |

We are going to use a black flush insert with chrome strap assembly. I have to create a couple of accurate counterbores for the two flush inserts - will update!.

|

|

Locking strap button at the back end of the body. Instrument looks much more complete with these on!!!

|

Left: The strap buttons have been added to the body of the instrument. This is the rear one where I had some good solid material to bolt into. Right: The is the strap button at the neck end. They are both locking strap buttons so they should do a great job. I'm continuing to work on the fine details on the guitar to finish and ship asap! |

Front strap lock installed. Now I need to get back to attaching truss rod cover, finishing saddle indents and getting this monster strung up!!!.

|

|

Just indenting enough to hold the srings in the correct place relative to neck and pickups, otherwise they would slide right off the saddles!

|

Left: The AMB saddles do not have indents to hold and position the strings so I am aligning strings and carefully adding very small string notches. Right: Fingerboard woods are a nice color after the conditioner was applied. Probably will have one more cleanup application after all the work is done setting up the guitar! |

This is the fingerboard after the conditioner was applied. I'll do another coat and cleanup before shipping.

|

|

Working on the surface of the fingerboard o make sure there's no traces of overspray from finishing and also to prep the surface for the application of wood conditioner.

|

Left: Doing a quick surface cleanup on the fingerboard after which I will add a couple of coats of wood conditioner to make it all look awesome. Right: Just for reference, I wanted to post the locations for the front and back strap lock buttons. It's a lightweight guitar anyway so these locations should work pretty well. |

This image shows the individual locations of the front and back strap lock buttons. Always good to illustrate before we make the final commitment!

|

|

Schaller S-Lock strap buttons were requested so I got hold of a set of those. I'll get them attached as soon as possible.

|

Left: Got the chrome control knobs I wanted for the push/pull pots AND the Schaller locking strap buttons!! Now I can get this thing finished up!!! Right: Change of plan - locking strap buttons are going to be Dunlop instead. I was able to get hold of a set and will now plan on the best locations on the body for these to be installed. |

We made a last minute change from Schaller to Dunlop on the locking strap buttons. I'll get these attached to the instrument body as soon as possible.

|

|

Keeping things moving forward, now going to add a little string detent into each of the ABM saddles.

|

Left: Spent the day with my electronics guy and resolved a lot of things! Got LED power supply taken care of and I am now moving on to establishing string detents in the ABM saddles. Right: This photo shows the modified control cavity with the discrete fiber optic system at the far left. I'm moving on to bridge saddle set up. |

The wiring and mechanics of the fiber optic LED lighting system is now fully installed.

|

|

Ready to do some installation and wiring to get the LED system up and running.

|

Left: Instrument is on the bench having several LED related components installed. I will be very glad to see this done and look forward to the results! Right: Had some measure of success with the LEDs, but ran into grounding and reverse-current issues that I could not resolve myself. Driving to see my Electronics Guru tomorrow morning. |

It's a bit of a drive, but it's the only way I can get a guaranteed successful solution so going to see Mark in the morning!

|

|

I received my resistors and some additional LEDs in the mail so I am now getting things ready to finish up this area of the guitar!

|

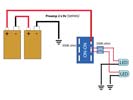

Left: I got my resistors and a few spare LEDs from Lighthouse so I'm working on getting the rest of the electronic work done asap!! Can't wait to get all these things finshed!! Right: Have a revised drawing for the LED circuitry so I'm going to get the lighting all hooked up so I can do some final testing! |

I verified this drawing with my electronics guru and now I'm anxoius to get everything hooked up!

|

|

Did a quick test on the side dot illumination using a random Amber LED - seems to work so far - going to get hold of some Purple LEDs and get this all set up!. F19 was slightly suspect but will hopefully resolve.

|

Left: In the process of setting up LED light source for the illuminated side dots. Customer asked if Purple color was a possibility - looks like it will be just a change in resistor ratings - will update!!! Right: To optimize these LEDs I apparently need 300 ohm resistors, Ordered some along with more LEDs for asap delivery. |

Further to consultation with my electronics guru and several sources on the internet, I need 300 ohm resistors to match the forward voltage ratings of these LEDs. They are on ther way while I work with other stuff!!!

|

|

Got the 18v power supply set up through from the battery cavity. Now need to locate resistors and organize the fiber optic cables in groups so that I can add the LED light sources!.

|

Left: Battery power is now connected both to the on/off LED switch and to a common ground I established inside the control cavity. Now I need to add resistors and set up the actual LED connections. Right: Was able to get the Protec case for this guitar today. Great solid protection, nice & compact, looks good and doesn't weigh too much!! |

Good to now have the case for this instrument in my hands. Have been using these cases since 2004 and I love them.

|

|

Very busy day but managed to get the split pots to talk to the pckups and output jack and split the coil circuitry successfully.

|

Left: Making progress - I got the two push/pull coil tapping pots wired up successfully and doing their job. Next will probably be the power supply switching and grounding for the LED power. Right: I have to get myself over to Protec Sound to get a case for this instrument - it's about an hour drive. More news on that very soon! |

Love Protec cases - they are th perfect combination of solid instrument protection, compact physical design and minimal weight.

|

|

Gettig some of the basics done for the electronics inside the control cavity. Will probably have to string the instrument up for testing. Will update.

|

Left: Getting some of the electronics established in the control cavity. Probably doing the magnetic pickup wiring first followed by the fiber Optic/LED work. Right: In order to properly test electronics I need strings on this guitar - I put on some spare ones for testing so that I can keep the custom set for the final setup. |

Nice to be able to test the ABM tuners and string retainers. Put some strings on the guitar so that I can get some sound out of the pickups and test the resulting output and coil splitting.

|

|

I re-installed the bridge saddles into the tuner assemblies. Things are coming together!

|

Left: Got the saddles re-assembled back into the ABM tuner units and I should be able to get some strings onto this guitar and finish up the electronics inside! Right: Two tasks going on here - one is cleaning the fingerboard surface so that I can apply wood conditioner. The other is adding magnets to secure the Truss Rod cover. |

Cleaning the fingerboard surface so that I can apply wood conditioner and bring out the beautiful colors and grains, also adding neo magnets in headstock for securing the Senchant truss rod cover

|

|

I'm individually fitting the six ABM string retainers in their little recesses in the headstock. Once I feel they are all seated properly I will get them secure in there.

|

Left: Getting the string retainers installed in the headstock - this is going to end up being a super-unusual design and quite a conversation piece when complete!!! Right: Had to monkey a bit with the height of the string retainers but got that done and istalled them with nothing less than gold screws to match the metal flake in the finish! |

Had to raise the 6 string retainers about .040 so that the string entry hole was just above the surface of the silver headstock panel. All good and got them all installed with gold screws - looking pretty cool!.

|

|

Using a laser-cut template to establish placement of the string slots in the nut.

|

Left: I used the laser to cut a very accurate string spacing template which I will now use to establish the string slots in the nut. I'll install the string retainers after that! Right: Got the string slots cut into the nut and now I am moving on to installing the ABM string retainer blocks into the recesses in the headstock. |

Slots have been established in the nut although I have to wait till the strings are actually on the guitar to finish the individual slot depths. Also started work on installing the headstock string retainers.

|

|

All 6 tuners are now attached and grounded to the instrument.

|

Left: All the bridge units are now grounded and attached to the body of the guitar. I'll now get the nut and string retainers installed and so that I can get a set of strings on this beast! Right: Working on shaping the nut and getting it securely fitted into the nut slot. Will also establish the nut slots for the strings. |

Installing the nut blank. Once it's in place I will carefully establish the string slots.

|

|

Got the two outer tuner assemblies installed. Will how fit the remaining four.

|

Left: Got the two outer bridge/tuners located and mounted. now moving on to install the remaining four. I will use sets of spacers to make sure they are positioned correctly. Right: Got the front ends of the tuner assemblies aligned and attached, now working on the spacing of the screws at the back of each of the units. |

Working on the last 4 screw positions so that all 6 of the tuner assemblies are in place!.

|

|

I'm carefully setting up the 6 ABM tuner/bridges so that they will all be correctly placed and securely attached to the guitar.

|

Left: Next task is to align and attach the six ABM tuners onto the top of the instrument body. Each of these will need a grounding wire running through to common ground in control cavity. Right: Marking out the two outside tuners and I will then attach them to the body allowing me to equally space the remaining four. |

Getting the two outside units attached first. Spacing is critical since tey follow the taper angle of the neck.

|

|

Getting started on the work in the control cavity. Need to run ground wires from bridge unit locations and run power supply through from battery cavity.

|

Left: I'm now working on the installation of the potentiometers and getting the fiber optic cables and the other wiring routed through and tidied up. Will also be running grounding and power wiring. Right: Since I have space for 2 batteries I'm wiring for 2 to power LEDs. This will yield longer life between battery changes. |

Connecting up terminals for battery power to the LED system for the fiber optic side dots.

|

|

Cutting little recesses on the CNC on the backs of the cavity covers for neo magnets that will hold them in place.

|

Left: Needed to cut fairly accurate recesses for the magnets that will be set flush into the backs of the cavity covers. Got them all cut and just need to glues them in. Right: My electronics guy gave me the best push/pull knobs, very well made just a little bigger than I expected. No worries - still plenty room in cavity! |

These push/pull knobs are the ones Mark recommended so I will go ahead and get them fitted into the instrument.

|

|

Pickups fitted - just need to add the height adjustment screws etc and they will be installed as a permanent part of the instrument!

|

Left: Installing pickups - this guitar is getting pretty scary - it has many features that I think are totally unique to this build! It's gonna be a very unique instrument!!! Right: The two pickups have now been installed into the guitar body. I am now looking at the layout of the tuner/saddle assemblies so that we can get these attached. |

I spent a good chunk of the afternoon working on these until I had them cleanly and comfortably installed in place. Moving on to getting th ebridge pieces positioned and grounded so they can also be attached.

|

|

Quick shot of the finished copper shielding before the electronic hardware wnd wiring all goes in there!.

|

Left: The control cavity has been fully shielded and I am now in the process of setting up and installing the two dual coil pickups into their respective cavities on the front of the instrument. Right: Now working on the final fitting of the two humbucker pickup assemblies. Once these are in and set I will add the ABM bridge/tuners. |

I am working on getting the best possible fit for the pickup assembles including the 4 wires that are connected to each unit.

|

|

Got started on the copper shielding of the control cavity. Once I get this task done I will be able to install the pickups and get their related wiring into the control cavity.

|

Left: Started on the lining of the control cavity with copper film. I'll cover the entire inside and the bottom of the control cavity lid for maximum shielding. Right: Before completing the copper shielding I had to fit the locking jack socket into the back of the instrument body. One more small step towards completion! |

Copper shielding almost done but had to fit the jack socket assembly before getting the last area shielded.

|

|

Very happy to get the pickup bobbins installed into the pickup covers. I will try to get these installed into the body as soon as possible.

|

Left: Got the pickup bobbins installed and fixed into the two pickup covers! Slightly tricky job as they have to be aligned and flush with the inner cover surface plus wires have to all exit together! Right: Right now making sure wiring channels are working and setting up fiber optic cables so that I can add the light sources. More info soon!!! |

I need to get these two cavities sealed and shielded but I'm making sure the wiring channels are good and setting up fiber optic cables for cutting and adding LEDs.

|

|

I applied copper shielding to the insides of the two pickup cavities.

|

Left: Pickup cavities now have their coating of copper shielding applied. I now have to fit the bobbins into the pickup covers and then we can get it all assembled. Right: Doing some dremel work so that I can fit the truss rod cover and the six string retainers into their rspective recesses. Fancy stuff! |

I have to carefully remove finish buildup on almost all the recesses. Right now getting the truss rod cover and string retainers to fit in place. Then I will probably add the nut.

|

|

Now that the covers fit nicely in the cavities I am applying copper shielding to the inside surfaces. I will have to do this also to the rear cavities.

|

Left: I sanded out most of the overpray to achieve a good fit and now the guitar is getting the copper shielding installed inside the two pickup cavities. Right: Next task is to fit the pickup bobbins carefully into the two pickup covers. Holes for exposed poles will need slight cleaning out as finish compound bleeds in there a little. |

Working on getting the four pickup bobbins to fit comfortably in the two pickup covers.

|

|

I'm testing the respective fit of the two pickup covers inside the recesses in the body. Typically after finishing they can be a little tight due to buildup of the poly-resin coating but I can use a dremel to remove that from cavities, test the fit and then add the copper shielding.

|

Left: Next task is to get the pickup bobbins to fit into the covers and also make sure the pickup covers fit into the body with copper shielding in the two cavities! Right: I ground out the overspray on the pickup cavities to the point where I was able to fit the two pickup covers in place! Now need to add the copper shielding. |

Spent some time removing the poly resin buildup in the pickup cavities so that the pickup covers would fit in their respective recesses. I may do some hand sanding to make sure that the addition of the copper shielding doesn't make everything too tight but so far so good!!!.

|

|

This guitar is truly unique in this planet, even galaxy! It's not done yet and it looks like no other instrument I have ever seen. The curly maple came out very 3D which is what I was hoping for when I chose the wood!!!.

|

Left: I endured horrific weather conditions to pick this instrument up from my finisher. It's a lot to take in - mind-boggling and beautiful. Right: Both the front and the back of this instrument are pretty amazing in terms of artwork and detail. I need to set up the cavities with magnets and shielding probably next! |

Lots os detail on the back of the guitar - the crop circle art looks very impressive! Colors, woodgrain and gold flake also very cool..

|

|

The fine gold flake in the body finish looked really good. Just as I had imagined it. Catches the light when you move the instrument!.

|

Left: Visited my finisher as he was not initially sure how a fine gold flake would interact with the finishing process. To me it looked just like my vision if a reflective dusting that didn't interfere with woodgrain! Right: I thought he did an awesome job on the crop circle - he told me however he thought he could improve on it by redoing!!!! |

I really did think this came out perfect, but my finisher wanted to do it a second time to make it even better.

|

|

This was the first stage of several applications on this guitar. We now have the black dye applied, then rubbed down to expose the white of the wood, then finished with Epoxy Resin. It will then be buffed and as far as I know the gold flake can be applied at that stage - then another clear coat over that!

|

Left: My finisher was kind enough to send me a couple of photos of the status of the finishing process. We can see here that he is creating the 3D look on the maple with the black trans treatment. Right: This is the guitar at the same stage but seen from the back. The black trans looks great even at this stage. More to come! |

Back is also starting to look awesome! I am in touch with him and will hopefully get more photos as we wrap up the finishing process.

|

|

Took the guitar to my finisher up north today. Spent a while explaining all the finishing details and promised to emails with photos highlighting wjat finish/color/masking/fill treatments are required on each area!

|

Left: Major step forward today - took the instrument to my trusted finisher. I laid out all the finishing requirements and will follow up by emailing all the details so that we all understand the requirements! Right: I communicated with my finisher and he's OK - making progress although I have asked him to do a LOT on this instrument!!!!!! |

TMy trusted finisher indicated that this big project should be finished in the next few days - can't wait to see it - trying to see if he can send me a photo. He's testing the gold flake over the black trans!

|

|

I'm cutting up the adhesive masking material and getting it all ready to be cut in the laser. I will of course test the cut on other material first, if that holds together I will create the two templates.

|

Left: I am now getting the adhesive masking material ready for cutting in the laser. If things go well I will get two templates which I can pass on to my finisher with the guitar! Right: I did a test cut of the crop circle mask on heavy paper to see how its integrity would be. Not too bad - need a few small adjustments. |

Tried cutting the entire template at full scale to see if it would hold together. Not bad - some elements are a little too close together so I'm going to do some editing on a couple of features but nothing drastic.

|

|

Trying to find a way to create this artwork on an adhesive mask - NOT an easy task.

|

Left: I have this artwork that I am trying to convert to an adhesive mask that can be used in the finishing process. May have to simplify a little to make it work - we'll see. Right: I'm maybe 3/4 done with the crop circle artwork - VERY hard to design it so that the mask I cut will not fall apart! I think I am getting close. |

This is pretty tricky to create - I want to hold on to the fundamentals of the design but at the same time create enough integrity so that the mask I end up cutting will not fall apart. Next challenge will be actually cutting the mask. Wish me luck!!!!!.

|

|

Sanding this guitar from bumper to bumper to get it 100% ready for taking to my finisher.

|

Left: There's a lot of sanding going on right now as I prepare the body for finishing. Even though we're looking at making an "industrialized" finish I want to give my finisher a good quality surface to work with. Right: Just about done with sanding but I have to verify some of the finishing details with my cutomer - stay tuned! |

I'm refining the fairly complex set of finishing requirements and at the same time working on a mask for some artwork my customer wanted on the back of the neck.

|

|

Doing a quick fill on the engraving on the back. If my finisher can comply we'll also try the "burn' effect but depends on what he can do. Will update.

|

Left: We decided to fill the engraving on the back so that it looks better and cleaner after finishing. I'll do it in pretty much the same color. Just sprayed some sealer on there to prevent possible bleed into wood. Right: Sealing up the back engraving with a clear filler. This will yield a flat surface which will work well with finishing. |

We talked about ways to make this area work artistically and figured the pre-finishing surface should be flat for best results. Filling the engraving with clear resin.

|

|

Getting the last piece fitted into a very nice looking headstock assembly. Talk about a one-of-a-kind guitar! Wait till you see it post-finishing!.

|

Left: Almost done with what is now a very cool looking headstock assembly. Just wait till you see if after finishing is done!! Moving ahead! Right: Doing a lot of fine sanding all over this instrument. I'm checking every area to make sure all surfaces are ready and properly sanded and prepped for the finishing process. |

Final sanding in process - needs to be sanded very smooth because we are applying colored trans finishing. No doubt it will look spectacular!.

|

|

Still working on the headstock assembly but now getting all these parts finally glued together. Will update more as we progress.

|

Left: I am now gluing the slightly recessed darker wood into the outer machined areas of the headstock. When this is set and sanded flush I will install the plate with the string retainer slots. Right: Perimeter inlay completed and now I have to carefully fit and attach the center section. A little tricky and not much room for error! |

Moving on through the headstock work - sides are in and sanded and now I'm working on center inlay to get it to fit perfectly before gluing into place.

|

|

Headstock recess being mechined on the CNC. I'll have to decide visually what the best depth will be.

|

Left: Work is under way on getting the headstock completed. Right now carefully cutting the recess for the plate we made. Will do the outer recesses after this is done. Right: There are several machining operations involved with this headstock design - right now I am creating inserts for the outer inlay. |

I have to machine inlay material for the top and bottom of the headstock perimeter. This will be the piece I will inlay on the top area.

|

|

Ready to set this little sub-assembly into the headstock. I'm inventing it all as I go!.

|

Left: I will recess this plate slightly into the headstock surface. Just trying to think of a way to make the truss rod cover easily removable if I do all that. Right: Setting the instrument up on the CNC so that I can machine a little recess for the new plate and also taking the truss rod cover thickness into account. |

I'm going to machine a recess the same shape as the new plate and if I do it right the truss rod cover will remain just a little higher making its removal easier when necessary.

|

|

We now have a plan for the headstock plate so moving ahead with that!.

|

Left: I selected a very nice piece of maple for the headplate we are going to create. I'll double check alignment, size and string spacing and then get it cut out!! Right: The headplate insert is now cut and looks pretty good so far. I plan to machine a corresponding recess in the headstock and inlay this piece. |

Tricky work but so far so good - it should look quite impressive when complete.

|

|

Testing the drawing I made onto the real-life guitar headstock. I'll make a few careful adjustments before I consider it complete then I will choose a suitable piece of material and get it cut. Not yet sure of the string retainer plan (back or front) but will be illustrating that too!

|

Left: I am doing testing with paper to make sure the shape we are creating fits the top of the headstock and the truss rod cover accurately. Right: I will make the headstock plate silver but right now establishing the exact shape based on string pacement and fit with the truss rod cover. Want to get this done so I can send to finishing! |

I will probably recess and permanently affix this plate into the headstock. It will be made of wood but will have a metallic silver finish applied. It will probably cost me extra due to the masking required but it seems the most stable way to get this done! I also favor the ABM chrome string clamps being on the front side - less chance of broken strings and quicker and easier to change strings.

|

|

My two challenges here are finding a chrome-like material that is machinable or I can cut on the laser, and making sure that cutting the brown areas out of the headstock veneer will work with the geometry of the back of the headstock. There's always a way!

|

Left: Getting closer -brown areas will be machined through to expose darker wood behind headstock veneer. Headstock will be black trans finish like body. White plate shown will be chrome or natural maple (like fingerboard). Right: We have decided to make the insert covering the string retainers a mostly silver finish. Shown in yellow! |

I'm using yellow on the computer just to make the geometry stand out while I scale and twek everything to fit. Going to cut a test piece first to make sure everything fits, once that's adjusted I'll make the final piece. May slightly recess it in the headstock - not sure yet.

|

|

I have a little freedom to shape the headstock to reflect the shape of Nantucket Island. We're brainstorming!.

|

Left: I'm doing some detective work since my customer wants a little bit of Nantucket Island incorporated in the headstock. We'll get there once we iron out a cool concept!! Right: The headstock on this guitar is going to be its own ndividual work of art. Right now I am exploring geometry for a plate that will represent water. |

I'm working with ny client to see if we can reflect the Nantucket Island form into the headstock. First stage is a plate that surrounds the string retainers.

|

|

This engraved area will be getting filled once we decide on the color.

|

Left: I sprayed a special sealer into this engraving so that when I add some filler the compound will not bleed into the maple wood. Always have to take precautions!!! Right: We are going to use some of the features that were explored on this image and try to incorporate them on the headstock of the guitar. I'll address them individually! |

There are a lot of features detailed on this drawing. I'm going to try to find a way to make most of them a reality.

|

|

Working on the final surface finish of the instrument. Feels nice already.

|

Left: I'm on the fine grain stage of final sanding. Working progressively from head to end of body making all the surfaces super smooth. Need to also dress all of the frets! Right: Working on the fingerboard and the dressing of all the fret ends to get that task out of the way. Almost done with the general sanding of everything too. |

Getting all the frets dressed both ends and doing a final surface treatment on the fingerboard before finishing.

|

|

As long as I am careful and patient this should work out OK for engraving the artwork behind the neck.

|

Left: I have to defeat a few of the laser's circuitry restrictions n order to get a whole guitar inside the machine. Anyway - I will go ahead and get the artwork engraved. Right: The burning of the custom logo was successful and looks really good where it is located! It will need to be filled to look best after finishing. |

I am very happy this job is done - it was difficult to set up and test and it was quite a relief to get it done. Looks great though!.

|

|

I want to briefly visit the size and angle and placement of this feature before committing but this photo mockup shows the approximate result.

|

Left: Getting ready to laser etch the personalized date into the back of the body near the neck. I have been sanding the instrument to a fine finish and this is one of the last operations. Right: I have discussed the finishing/tints with my customer. We're not going to do the original blue tint plan, but I will detail the new concept here! |

My finisher said he can add small metal flake to the finish we will be applyiing. I tried to find a photo of something similar on the internet but could find nothing. Basically it will be clear to show wood with a sprinkle of small gold flake included.

|

|

Doing some final sanding on the neck to body transition. We're almost done with shaping and sanding and we'll be headed to finishing soon!.

|

Left: Neck is now at the desired thickness and profile and I am working on finishing the body transition where my customer wanted a nice smooth slope from neck to body thickness. Right: Sanding coninues as I prep for this guitar going to finishing. Trying to establish the best color and finish formula to match my customer's vision! |

Doing some final sanding on the neck to body transition. We're almost done with shaping and sanding and we'll be headed to finishing soon!.

|

|

Holes and recesses for controls are done - still need some sanding to blend everything in.

|

Left: I got the three control holes done in the front of the body. The recesses give the pots and switch a flat surface to mount on while blending with the curved top surface. Right: Doing some final sanding on the back of the neck and in a few other areas around the body to get everything ready for the finishing process. |

Getting the last of the neck sanding done and measuring carefully as I go.

|

|

Just about to machine holes and recesses for control knobs and pickup switch. Based on the curve on the instrument to I will probably do a raduised recess for the two knobs.

|

Left: I'm just about to cut and recess the holes in the top for the two pickup volume controls and the 3-way selector switch. Have to be careful about positioning. Right: We considered putting a 3rd party sustainer in the electronics of this guitar but decided after some research we're probably safer doing that externally if needed. |

Good results from machining for the Neutrik locking jack socket assembly.

|

|

Managed to get the instrument set on the CNC in such a way that I could access the back of the control cavity for the jack output assembly.

|

Left: The guitar is in a tricky little set-up right now to allow me to machine out a suitable recess for the output jack socket. Should work out fine. Right: This is the guitar with a jack socket installed - everything ened up working out just fine. The actual jack socket will be chrome/silver finish to match the rest of the hardware color. |

Good results from machining for the Neutrik locking jack socket assembly.

|

|

Need to mark outand pre drill 12 holes for the string clamps.

|

Left: The locations for the sets of holes are being marked out on the headstock. Might refine the lower curve just a little but when we are done. Right: Back to sanding everything to get the last few details done on this guitar. I still have an ebgraving to do on the back of the body and an output plug socket recess oon the side! |

Getting the surfaces ready for final finishing. Lots of sanding to do.

|

|

Descriptive text coming.

|

Left: I need to do a lot of sanding around the body and the area where the neck joins the body. I will also do a final sand on the back of the neck. Right: I am using ABM string clamps on the headstock area. Right now making sure they are laid out on the string paths. I have a pattern of holes to drill so that these can be installed. |

Getting things ready to have the string clamps laid out correctly on the headstock.

|

|

I finally did get the guitar set up in such a way that I could machine these slots. I'm now getting ready to get the actual machining done.

|

Left: Two things shown here. One is the setup holding the guitar in a very strange position for machining the holes. 2nd is the approximate arrangement of the machined holes through to the inner chamber. Right: OK - the slots have been successfully cut all the way through to the closest internal cavity - it all went quite well actually!! |

The three slots are now successfully established and I can move on! We are getting close.

|

|

I'm hoping I can set the instrument up on the CNC in such a way that I have access to this area of the upper body. Slots will probably be 1/8" wide and go through to the closest inner chamber.

|

Left: Not a great photo but this shows the approximate layout and shapes of the holes we are planning to establish in the front of the upper body half. Setup for this should be interesting! Right: This is part of the fairly comlex setup that will be required to cut the three slots in the upper horn. Should be ok as long as I am careful! |

The guitar needs to be set up on the machine table in such a way that I can work round the neck and get the slots at just the right angle.

|

|

I'm working on a nice pattern of holes through to the inside chambering.

|

Left: There's a small area on the top of the body where we are going to drill a little pattern of holes connecting to the inside chambering of the instrument. Right: The holes through to the inner chambers have a special pattern my customer woulld like so I am working on a setup that will facilitate the initial machining work. |

The goal here is to create three slots as illustrated which connect to an inner chamber in the front section of the instrument body.

|

|

Looks good and will be even more impressive after finishing! Moving along to other tasks!

|

Left: I have the inlay glued into the tops of the two pickup covers. Next I need to look at the breathe holes and a couple of other features requested by my customer! Right: Text and picture coming. Right: Doing some final carving work so that I can get to the sanding stage and clean up the whole body and neck areas! |

I have to create a nice edge break all round the back of the body. Also working onneck-to-body transition. Will be drilling aroma holes VERY soon..

|

|

Recesses cut into pickup covers and they are ready for inlay.

|

Left: Recesses have now been cut into the tops of the two pickup units and I will now get some Walnut veneer cut to match these and get that glued in to complete the two covers. Right: Work in progress -I'm trying to get everything to fit and line up, especially with the magnet holes. Will get it done tonight! |

It's a little tricky but we're getting there. Some small adjustments and we should be done.

|

|

The counterbored holes for the adjustment screws are done and now we're going to do the cutom inlay on the top surfaces.

|

Left: Before machining the top surfaces for the inlay I had to finish drill the 4 adjustment holes and also machine concentric counterbores in each one for the adjustment screws. Right: Due to the proximity of the holes to the adjustment screw counterbores, the bridge pickup will look like this. Very slight adjustment. |

Just trying to keep these features separate- it would look strange if the were to run into each other.

|

|

Another step in the race for the finish line - the truss rod cover!

|

Left: I am adding a personalized trussrod cover on the headstock. Cut this one out on the laser. May fill the text with one of the neck inlay colors. Right: Doing some measuring and calculations so that I can create machine paths and artwork for the laser to accurately place the walnit inlay material on the tops of the pickups. |

Doing the math on the geometry of the little channels and inlay material on the tops of the two pickups!

|

|

I am getting ready to create inlays in these two pickup tops possibly usng walnut material.

|

Left: I am getting ready to do some decorative inlay on the top surfaces of these two pickup covers. It will add nicely to the industrialized theme on this guitar. Right: This is my ciustomer's vision of Crop Circle art along the back of the neck. We have a gold color we may use to achieve this and I am working on a method to apply this! |

I have only once tried and inlay pn the back of an instrument neck. If this works it will bevery unique and unusual!!

|

|

I am planning to do some artwork in this area - have to figure out the best way to use the available space!!!

|

Left: Looking at the back/top of the guitar body. We have two features going on in this area. A set of holes that connect to an interior chamber and a series of crop circle icons. Right: This is the cover for the truss rod access area which is custom-engraved and will probably be filled with a contrasting compound before finishing. |

The truss rod cover is cut and engraved and I will be working on the rest of the headstock features to get that area completed!

|

|

These two inlays should look very cool once the insdustrialized finish is completed!!

|

Left: Both the back covers have now been filled and leveled and are ready for fnishing. Have a little more shaping on the neck and body and need to get this completed asap as my finisher has a big Covid-related backlog! Right: Looking ahead to my upcoming challenges - I will be customizing the headstock soon - more details coming! |

The headstock may have a slightly geographical theme - working on the geometry right now!

|

|

I'm anxious to get the body shaping and sanding completed so that I can get the whole instrument ready for the finishing process!

|

Left: Back working on the neck and body shaping so that I can get all that finished asap. I'm roughing out some of the basic shapes and will do the final work with hand tools. Right: In the process of finishing up the inlay on the two back cavity covers. Once all the resin has cured I will flatten surfaces and prep for finishing. |

Sealing up the inlay on the two back cover plates!

|

|

Took me 3days to clean up this little bugger! I used a lot of tint whichended up making the set solution atiny bit less glasshard thn it should have been. Had to sand the excess off where normally I could have just scraped it. Nevertheless it come out nice - have some final cleanup to do but otherwise DONE!

|

Left: Almost there with the Flower of Light inlay - I will actually come out looking pretty good once we are all done. Was a lot of work to remove the buildup of filler! Right: I was able to get the inlay material embedded into the battery cover plate of the guitar. I need to clean this up and level with a clear filler next. |

Battery cavity cover now has the inlay material attached and I will have this part of the guitar ready for finishing very soon!

|

|

The FOL inlay is so fine and detailed that I will probably not succeed in getting a solid orange in the recesses. I mixed the resin as dark as I could and I expect the results to look good but perhaps more "industrialized" than a solid orange - we will see. It will look pretty cool no matter what! Esp[ecially qafther the whole instrument is finished in its final colors.

|

Left: I'm working on getting the Flower of Light inlay filled first but I'm also getting ready to cut blue shell for the battery cover logo too. It will be nice to have these done! Right: I spent some time on the battery cavity logo to get anice fit with a coupleof different shells. Both are nice- will probably use the one on the right.

|

Both shells looked great but the one on the right is the same material as trhe blue inlay on the fingerboard. I can always use the other logo somewhere else.

|

|

Engraved both plates in the laser this morning and results are good. Need to get them cleaned up then Flower of Light will get orange compound and the battery cavity cover art will get shell - both to match colors of the inlay on the fingerboard.

|

Left: The two covers are right out of the laser engraver so they need to be cleaned up a little but everything so far has worked out well. Will be doing some sanding before filling. Right: I sanded the two back covers down to their finihshed thickness and I can now focus on getting the recesses filled with their respective colors. |

Back cover plates are now flush with body surface and cleaned up. Will get started on the inlay work.

|

|

Test burn on the laser so I can evaluate the results before comitting to the actual cover.

|

Left: Doing a test of the engraving on a similar piece of maple to see how the artwork looks. I will have to find away to embed orange filler in this as it is too detailed for shell. Right: Experimenting with filler as the detailed logo has very thin lines. I think I have the best balance of line weight in the artwork and filler formula should work. |

Lots of testing going on to try to make sure the Flower of Light logo will come out looking OK in an orange color to match the front inlay.

|

|

Now have some nice clean artwork ready for engraving onto the two back cover plates..

|

Left: Just finalized the artwork for the two back covers so I will get these designs engraved as soon as possible and we'll be closer to getting this guitar stained and finished. Right: This is the final layout for the artwork on the back covers. Wedecided the battery cover inlay will be blue and the control cover artwork will be orange. |

These are basically the vector files I will be using to engrave this artwork onto the two covers on the laser. Should be interesting!

|

|

This FOL design is a little more solid looking. Will leave the choice to my customer though....

|

Left: We decided to rotate the logo on the right 90 degrees. Also - on the left is another version of the Flower of Light design for consideration. Right: I wasn't able to download a clean enough version of the flower art to convert to vector so I decided to draw my own one. Not as easy to do as you wouldy think! |

This will help with laser engraving the pattern into the cavity cover.

|

|

I'll need space for 6 LEDs and I will have to do some research related to the resistance required in the circuitry.

|

Left: Another interesting challenge I have is the colors of the LED lighting. We are trying to use 6 different colors so I need to see if I can accomodate all these LEDs. Right: I received my string clamps by ABM all the way from Germany! I will get these unpacked and will post some pictures of how they will work on the headstock area. |

Delivery of these units was surprisingly quick - I can now plan on getting these arranged on the headstock the best way.

|

|

I have used a lot of AMB parts in the past - not the cheapest, but definitely the best quality. Items like these are very hard to find.

|

Left: After a lot of research the only quality contruction string retainers in chrome for guitar out there are those made by the German company ABM. I'll probably get these. Right: My customer wanted a more gradual blend between the back surface of the body to the neck. I'm working on grinding that and blending everything together. |

Neck to body transition is going to me slightly custom so I am working on that right now.

I have used a lot of AMB parts in the past - not the cheapest but definitely the best quality. Items like these are very hard to find.

|

|

Current goal is to get the neck sanded down to finished shape and thickness.

|

Left: Did a lot more sanding and shaping to the back of the neck to get it close to finished size. Also working on the neck/body transition to get that in a place where I can consider it finished. Right: Working on artwork for the two back covers right now. I need to get both of these engraved and filled before going to finishing. |

I am working with both of these pattern files to get the best look..

|

|

Not a huge amount of choice out there in chrome single string retainers that could be discretely mounted.

|

Left: I'm looking for string clamps for the headstock end of the guitar. They could be on the front or the back of the headstock as long as I can find nice chrome ones. Right: I was thinking that this logo from my customer may well be able to exist on the battery compartment cover since we have the other artwork on the control cavity cover.. |

Just a thought but if we have the Flower of Light on the control cavity we could put this one on the cattery cover in a matching filler color.

|

|

Shaping and sanding the neck and its tyransitions with the body and headstock.

|

Left: Working on the final shaping of the back of the neck as we approach the finishing stage. I also need to establish a set of string retainers for the headstock. Right: I have to reduce the back covers to final thickness but we are also planning to include an inlay of the "Flower of Light" in some complimentary color (probably shell of metallic). |

This should be a very nice feature on the guitar. I need to find some clean art that will allow me to engrave somthing like this.

|

|

I think these covers are shaping up to look really good on this instrument.

|

Left: Now we are getting somewhere - first of the two very custom pickup covers has been cut and I will now start on the bridge p/u cover. After they are both done we'll look at the custom inlay on each. Right: Quick update on the body with the pickups in place - I'm now getting back to final shaping and sanding around body and neck. |

Pickup covers ready for final detail, I have a back cavity cover to do some inlay on. Working on getting the body and neck finished.

|

|

A little scary as I only get one shot at getting each pickup cut with the correct geometry. Always safer to test cut in some scrap material first!.

|