|

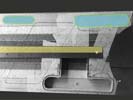

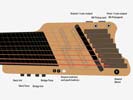

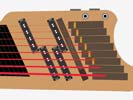

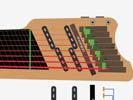

Setting up to cut a modified chember on the back of the bass. This will allow everything else to finally FIT!!!!

|

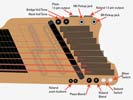

Left: The upper chamber has been re-sized and that will allow the pickup selectors to live next to the momentary switches and in doing so, make room for the controls and outputs at the bottom! Right: I discussed the electronic package in this bass with my electronics guru in Palm Desert today. Seems like the best possible plan!! |

I'm planning to have the bass stay at the electronics shop for a few days so that we can look at the best wiring plan, installation layout and get hold of any other electronic hardware needed to fit inside. When it returns from the finishing process we want to be ready to do a quick and efficient install of pickups and electronics.

|

|

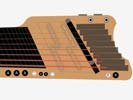

This is not physically done yet but will have to take place before finishing. I found away to include the rotary pickup slectors on the top surface next to the Roland program scrolling momentary switches. Parts are kinda expensive but I have no other way of getting all the required hardware in the bass. The good thing is that they will be easily accessible, they will not be disturbed or acidentally rotated while in use and since they will be recesses, they will be low profile enough not to be very noticeable from the front. Image is an artist's impression of the two knobs so they may end up a little smaller and closer together (they are only 12mm diameter)!

|

Left: I can't fit both 13-pin outlets + two stacked pots + two 1/4 inch jack sockets + two pickup selectors in the bottom cavity. I did find a way to install the selectors in low profile on the top! Right: Upon the CNC ageain this time to slightly re-size the upper chamber. This will allow all the electronics to fit into the body of the bass!!! |

On the CNC where I am re-machining the upper recess. This will help tremedously.

|

|

Ifwe dont go active on the Piezo feed we will not oly have a very poor and weak signal but will have problems blending signals.

|

Left: Another detailed meeting with Mark, and in order to make everything work together the system HAS to be active. Good thing will be that power drain will be very low so batteries will last a LONG time. Right: My challenge is to somehow create enough room for all the pots and outlets on the body. I'm close but need to do some work. |

I need to get this bass into my finisher's shop as soon as I haveworked out all the electronic issues. My electronic dilemmas are mostly based on overcoming significant grounding issues with so many components inter-connected. Not an easy job!

|

|

Current questions I am trying to answer: In passive mode, can I blend both pickup outputs to the Roland and retain the independent signals to the 1/4 inch jacks. This would, if possible at least give us Roland and Mag pickup blended options without having to go active.

|

Left: Mark has been informing me of the difficulties getting a usable piezo feed from a passive system. I want this bass to be the very best it can be, so looking very closely at both active and passive possibiities. Right: looking at the possibility of moving 13-pin outputs to the back end of the body as shown. I need to create more space! |

With all the controls required, and the finite amount of space, I would definitely benefit from moving the two 13-pin outputs to the far end of the bass, and in doing so, create room for all the other internal hardware. This is only a mockup to show the goals related to placement - in reality each output would have its own mounting plate for stability. Doing this would give me a chance to fit in all the other required controls.

|

|

I need to get this bass into my finisher's shop as soon as I haveworked out all the electronic issues. My electronic dilemmas are mostly based on overcoming significant grounding issues with so many components inter-connected. Not an easy job!

|

Left: Working on the neck transition to get it finished. Goal right now is to get this instrument into finishing as soon as I can. Waiting on GraphTech for some additional technical stuff. Right: More sanding and shaping around the neck/body transition to get that nice and smooth and well blended together. Almost done with this! |

Doing some sanding to get the neck feeling as comfortable as possible - also sanding at the transition with the body to get that area ready for finishing.

|

|

Two compact rotary selector switches which may solve many of our integration challenges in the wiring of this instrument.

|

Left: These took a little more time to spec out and locate but VERY happy to now have them. They can provide a very customizable choice of pickup selection options. Right: Two things going on right now. Cutting access through the headstock veneer for the two truss rods ends, and also sanding the neck to its final thickness and profile. |

Ground out the access to the two truss rod ends -still need to sand it down and get it all cleaned up.Also sanding neck profile and some other areas..

|

|

CGreat to get these controls in the mail. They will provide a very important space-saving solution for the magnetic pickup volume and tone controls.

|

Left: Just received one of the electronic hardware orders. These are special compact dual concentric pots wjich I will be able to use for the magnetic pickup feed. Right: I'm looking now at ways to incorporate the possible use of two rotary selectors suggested by Mark to give us an extremely flexible array of sound options! |

The electronics are complicated and work-intensive in this project for 3 main reasons. 1) All 3sound sources have to work together without grounding or signal strength issues. 2) Pickups need to have multiple selection options and go to dedicated output sockets while still providing magnetic signal feed through Roland. 3) Physical space based on size and shape of body is pretty limited, we are almost at the max!.

|

|

It was worth the drive to take the bass out to my electronic guy's shop so that we could evaluate the space we have to work with and how some of the controls might be best arranged.

|

Left: Brought the bass to my trusted electronics guy in LaQuinta and we discussed the hardware necessities to make the pickups, piezos and Roland all work together. Now have more hardware to order! Right: I simplified Mark's drawing a little bit to show what I think may be a super-flexible way to get the most out of the mag pickups! |

Customer wants to not only have the magnetic pickups go to separate outputs but also beable to separate the feed from each of the 4-string coils! Mark came up with this solution. I have to however make sure I can fit this in the body!!.

|

|

Mark and I are talking every day on this challenge. Passive pickups have a hard time integrating with systems that need to be active and we're looking at what electronic systems might provideus all with the right and most flexible capabilities.

|

Left: One of our challenges electronically is that the MIDI and piezo systems will have grounding issues working with the passive pickups and related switching. We are looking at what setup might avoid all of this. Right: Mark and I have put alot of development hours into avoiding electronic and grounding conflicts in the onboard systems. |

Getting close with some creative plans to make everything work. Mark gave me a drawing to evaluate in terms of fitting everything needed into the existing body. The two passive pickups need the most attention.

|

|

RCrazy day but I had a little time to create the lid for the (possible) battery cavity).

|

Left: Cut a matching Wenge lid for the cavity. Mark and I are doing everythig possible to accommodate all the switching requirements for the various sound sources on the bass! Right: Cavity and lid have now been established and we have a nice blended cover. This cavity will provide space for any batteries we may end up needing. |

Battery cavity for two 9v units has been created should we happen to need that.

|

|

Keeping things moving - bettery compartment will be machined and I'll create a matching grain lid for it.

|

Left: Will be cutting a compartment for two batteries if needed. The cavity will have a perfectly matched Wenge lid attached with neo magnets so it will be very discrete when seen from the back. Right: Got the instrument lined up and clamped on the CNC machine table ready for me to cut out the cavity space for batteries. |

Ready to get this cavity cut. Glad I have some space I can use on the back. Will look fine with its matching grain cover.

|

|

Just about to machine the two holes for the Roland program selectors.

|

Left: Got the bass up on CNC to cut the holes for the Roland scrolling buttons. I will do final fitting of the two buttons after the bass comes back from the finishing process. Right: Now have holes for Roland program scrolling buttons. Moving on to cutting a cavity and lid for the anticipated power for Roland and maybe GraphTech. |

One more pre-finishing task done. Will get the rest of the holes in and finish neck and headstock carving!.

|

|

This area blends really nicely now. I still have to open the areas up for the truss rod access butdefinitely gived the headstock a much more finished look!.

|

Left: I ended up adding a black veneer on the string bending area because it was willing to bend where the Wenge would not! This matches the fingerboard material really well. Right: One area I know will not change is the two buttons that will be used for scrolling Roland through MIDI programs. Going to pre-drill for those! |

Ready to establish two holes for the scrolling buttons for Roland.

|

|

I want to get the back of the neck at the body shaped in such a way that the upper frets are as accessible as possible for the player's hand.

|

Left: I am waiting for feedback from Graphtech to see if I need 9v power to supplement the signals from the piezo inputs. In meantime I am finalizing neck to body carving. Right: Making calculations on what depth I have available for battery cavity since I have a strong feeling we will need at least one to keep everything active. |

In my efforts to keep things moving and based on some feedback I am getting I will create a cavity on the back of the bass that can hold a couple of 9v batteries. If by some chance they are not needed it will be a gear cavity for picks etc!!!.

|

|

The Roland is a closed system that will do its job per their circuitry guidelines, but since we are trying to isolate pickup signals and bend some of the Roland rules, we are investigating. Similarly with Graphtech, the piezo signals need to be combined with other systems signals and I may need a specific circuitry! Mark has cautioned me that some of these systems may not work together without electronic conflicts.

|

Left: Based on some very helpful feedback from my electrics expert, I am exploring some electronic questions with both Graphtech and Roland to test the limits of compatibility! Right: Adding a veneer in headstock area to blend with the rest of the instrument. Also reducing the mass of the headstock area to a minimum before finishing! |

TI'm going top veneer this headstock forward area under the bending area so that it matches the darker grain on the center of the instrument.

|

|

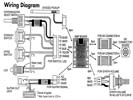

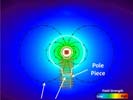

This is part of the Roland wiring diagram without the power supply components. We are investigating whether the circuitry will permit all the blending we want to achieve without the need for the Roland to have a 9v power supply. It gets complicated and I am very lucky to have a musical instrument electronic tech to assist me with this stuff!

|

Left: I am in frequent communication with my electronics expert, who has all the technical requirements for this bass. He is analyzing what the pickups, Roland and Piezo sources can actually do together. Right: I had consulted with my finisher and he use custom tint to mirror the back wood combinations on the front (artist's impression) |

My finisher saw the bass and can mirror the back colors onto the foront of the bass (which my customer really liked) so we are going to do that.

|

|

We're hoping to have piezo output from 8 strings to one of these outputs while the Roland MIDI feed comes out through the other. We are looking at the technical requirements of the Roland to see if this can all be achieved in a fully passive environment.

|

Left: I am setting the bass up to cut the recesses for the plugs that are required for the MIDI and the Piezo output signals. They will be held in place by two rectangular plates. Right: Slight changes to jack socket positioning to keep the plugs as far away from the player's hands as possible. Moving ahead carefully! |

It seemed very sensible to move the two 1/4" scockets as far from the player's hand as possible. We are looking at the various combinations of sound outputs right now - the Roland only really permits one wiring scenario so we're looking at ways to combine mag signals and piezo.

|

|

I'm final shaping and sanding the entire body of the instrument.

|

Left: I'm doing some final work in the fitting and sanding of the pickup cover/ramp which will be going to finishing with the bass and the other cover pieces for rthe back. Doing a lot of sanding! Right: Last thing I have to do to the body is cut the holes for the various sockets and controls. I'm starting iwth the MIDI and piezo units. |

Now machining the holes that will permit fitting of the electorics after finishing is done.

|

|

Three cavity covers have now been machined to very close to their final thickness. Last couple of tasks before finishing will be sanding the final neck thickness, and blending the transitions between neck, body and headstock area.

|

Left: Almost done with back of bass - I need to level the three cover plates flush with the body surface and then finish sanding the neck areas and we will be ready for finishing! Right: Cover plates have been finished for thickness and I am moving on to the final sanding of the neck and neck/body transition. |

I am now sanding the back of the neck to get it to the optimum thickness and profile. In doing so I will be also working on the transitions between the instrument body and the headstock area too..

|

|

The back of the bass is now done with the cavity machining work. I will thickness and fot the three covers next and start some sanding work.

|

Left: Now have all three access holes cut in the back plate so I can get this instrument off the CNC and fit the covers and get some final sanding work done! Right: I am now reducing the thickness of the three covers so that we have a nice flat and complete back to this instrument. I'll attach these covers with small neo magnets. |

I will be machining and sanding the three covers to their final thickness.

|

|

Grinding off the extra material on the beck plate to blend with the rest of the instrument.

|

Left: I left some overhang above the neck joint area so now I am sanding off that extra material so that I can blend the geometry of the neck to body area. Right: Now opening up the three cavity areas on the back such that we will be leaving a shoulder on each one for the covers to sit on and the placement of the retaining magnets. |

I am starting a little undersize on each one as I want some control on the final size that I end up cutting.

|

|

Gluing and clamping of back plate in progress. I will leave it overnight to make sure it all sets perfectly.

|

Left: Gluing of back plate under way. I was very careful to position it as well as I could. It will be really good to have this final part of the bass assembled!! Right: Back plate is now on the instrument and I am doing some surface cleanup at the moment. Then I will put the bass up on the CNC and mill out the cavity access areas. |

Back glued on - now I have to create the cavity openings and then I will finish necktransition and body profile.

|

|

Final sanding and alignment checks done and I am now going to get the back plate attached to the body.

|

Left: I did some careful marking on the body to make sure I am placing the back plate in the best possible position for the cavities below. I am not getting tooling together to attach the plate. Right: Setting up to get the back glued on. Quite a tricky setup as I want to make sure the plate is aligned accurately during the clamping process. |

Everything always wants to move when you put glue on it and I don't have any places to drill locating holes & pins. Just need to take it slowly and it should work out fine.

|

|

Carefully gluing the inserts intpo the recesses on the inside surface of the back plate.

|

Left: Now gluing the inserts into the back plate. Doing one side at a time to make sure the inserts are seated properly in theit recesses. Right: Back plate now has all its inserts done for the three covers. I will have to cut holes to match those cut in the back of the body but may do that part after the back plate is clued onto the body. |

Back plate has been filled and leveled.All it really needs is asanding all over to clean it up from glue marks. I'd like to get this on the instrument body as soon as possible.

|

|

The three recessed areas inside the back plate have now had material fitted. I will glue these in and sand everything flush.

|

Left: I just cut some material in the laser which will fit in the back recesses and create the nesting for the three lids. None of this will be seen when the back is on. Right: Here's a quick photo of the other side of the back plate. When these inserts areinstalled I willmachine out the through holes and the back plate can then be attached. |

Back plate with the recessed areas for the three lids.

|

|

These three recesses should work out fine - I am anxious to get the back plate on the instrument and consider that part done!!!.

|

Left: OK - happy to say that the three recesses are done and I can now move ahead to what should be an easier task of cutting and fitting three inserts. Right: This photo shows the front and the back of the instrument side by side. Once I get the three inserts into the recesses I just cut, the back can be attached. |

I am in the process of creating the three filler pieces that will fit into the recesses I cut in the back plate. Will make a lot morse send whan I post the completed pictures.

|

|

First of the three recesses cut. I'll be installing material into these recesses which I hope to be able to cut on the laser. If not I can machine them on CNC.

|

Left: First cover hole is recessed - now getting the other two done. This will create nice neat covers for the back of the instrument held in place by magnets. Right: I'm now cutting the third and most tricky of the recesses due to fact that there is not a lot of spare material around the bottom of plate. Just have to be careful. |

Getting started on the third recess which I'll need to be very precise and careful with due to wall thickness.

|

|

Second wiring channel is done so I can start working on prepping the back plate and getting that attached.

|

Left: I machined the second wiring channel in the back surface. This one provides a little space for the wiring exiting the circuit board. I think these should be sufficient to the best of my calculations! Right: I am ready to cut recesses in the inner surface of the back plate. This will create pockets for the three cover pieces. |

Gettig started with the little switch cavity. I will becutting a recess into which I will glue afiller piece to create a step (around .150") for the lid.

|

|

Just about to machine a few wiring channels on the back so that the body is ready for the back plate to be attached.

|

Left: Setting up right now on CNC so that I can machine a few wiring channels in the back face, There are a LOT of wires coming and going from that PCB to different places on the bass! Right: Got the first of the back wiring channels machined which connects the PDB to the two Roland scrolling program switches. |

One of the wiring channels cut - the other one is a bit more involved but should work out fine..

|

|

Top pate now part of the instrument assembly and looks good so far. Need to do some cleanup sanding and then get wiring channels on the back finished up.

|

Left: Top plate now glued on as a permanent part of the body assembly. Now I have to do some machining to provide some wiring channels on the back of the body before back plate gets attached. Right: I am now sanding the perimeter of the body to blend in the edges of the top plate. Then I can cut those channels in the back. |

Using the spindle sander to clean up glue and blend the edges of the top plate to the rest of the body.

|

|

It's a quick safety precaution, but a paper impression of the milled out areas helps a lot once the top has been attached.

|

Left: Before attaching the top plate to the body, experience has taught me to take a paper impression of all the recesses so that I can know exactly where they all are after they are covered by the top! Right: The moment of gluing on the top plate has arrived. Next will be some cleanup and machining on the back face. |

Top plate of the instrument is now being glued on. Once this is dried and set I'll clean up the perimeter and machine the back face of the body to finish recesses for wiring etc..

|

|

I am getting ready to cut wiring channels for the scroll buttons and mostly for all the wires coming off the PCB.

|

Left: Back wiring channels need to be cut. There are a LOT of wires coming off the board, many of which will go to the 13 pin output. I'm trying to plan the best orientation and wiring channel placement! Right: One more important operation under way - I'm gluing the dark veneer onto the joint face of the back plate of the body. |

I am gluing the dark veneer onto the back of the back plate.

|

|

To the best of my calculations this operation completes the work on top of the body and I should be able to glue on the top plate.

|

Left: Top wiring channels have now been machined. It was very importqant not to put a channel where a retaining screw would be, so everything has been as carefully planned as possible! Right: The back plate needs the decorative dark veneer applied to the inner side so I am going to get that done so that it can also be attached! |

Back plate needs two things - one is a dark veneer, the other is to have recesses cut for the lids. As soon as the veneer is on I will do that.

|

|

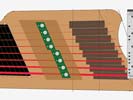

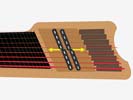

I will be machining these two channels for wiring related to pickups, piezos and grounding wires. Afther doing these the top can be premanently attached!

|

Left: I will be machining a couple of important wiring channels in the top of the body. Green is pickup wiring and red is a channel for Piezo and grounding wires. After that the top can go on. Right: Bass is on CNC for three wiring channels. Pickup wires, piezo wired and ground wires and also the wiring from the Roland pickup. |

I am going to machine a set of three wiring channels based on the anticipated locations of all the other controls.

|

|

Top plate in the vacuum press getting some dark veneer attached to the bottom (joint) surface.

|

Left: Now gluing a dark veneer onto the bottom surface of the top plate. This will allow me to get the top plate attached to the body of the instrument and it will yield a cool double pinstripe accent. Right: Dark veneer has now been successfully applied to the back of the top plate. It will be going onto the instrument soon! |

Dark veneer applied and cleaned up and now I have to cut a wiring channel on the top of the body. Once that's done I believe the top plate can be glued onto the instrument!.

|

|

So far so good on the cavities. Once I apply a veneer to the joint surface of the back plate (to match the front plate which already has one) I will do some machining to provide a location surface for each lid.

|

Left: Cavities ready, next two tasks will be putting a decorative veneer on the joint face of the back plate and cutting a few wiring channels in the back of the existing body. Right: I now have the back plate in the vacuum press where I am gluing on a maple veneer to match the top plate. May also do a dark veneer. |

Since the top and back plates are matching up with a maple center core on the body I will probably add a dark veneer to both top and back for a fancy double contrasting pinstripe.

|

|

This cavity will provide space for the Roland momentary scroll switches.

|

Left: Now cutting a smaller cavity which will house the two switches used for scrolling up and down through MIDI options for the Roland system. They should end up being pretty discrete. Right: Moving on to the third cavity which will house the rest of the knobs and switches required for Roland system and pickup blending. |

Third cavity will house potentiometers and switches. Once this feature is done I will set up for machining connecting channels for the wiring between all these electrical parts.

|

|

Each of these openings has to be recessed and then plugged with another piece of wood accurately cut to fill the recess. It will make more sense when I post pictures of the end results!.

|

Left: One of the other important machining jobs I have to do is to create recesses for the three lids on the back. First operation is to machine recesses in the back plate from the inside! Right: In this operation I am cutting out the lower half of the main control cavity where the output plugs and controls will live. Will move on to the other two. |

Now cutting the second stage of the control and output cavity..

|

|

These lid pieces will be thicknessed and configured to fit beautifully into recesses in the back plate which Iwill be machining next.

|

Left: Lid pieces have been harvested out and I am now back on the CNC where I will be machining out the 2nd and 3rd cavities and also adding features inside the 1st cavity. Right: Bass back up on CNC so that I can finish machine the control and electronics cavities to full depth in the three locations. It will be great to have this done! |

This is pretty much the last complicated machining task I have to do before I move to final shaping and other prep for the finishing process.

|

|

The two aread in blue/green are the lid perimeters and cavities for the remaining controls.

|

Left: While I have this specific setup on the CNC it makes sense to do the initial machining work to all three cavities on the back. I am going to go ahead and harvest the other two covers from the back plate. Right: Second and third cavities covers under way. It has been a lot of work already but results are mostly as planned! |

Removing the top two cover pieces from the back plate.

|

|

I would call this a success - the cover has been harvested out and I can now go ahead and machine other parts of this lower cavity.

|

Left: The first stage worked and I was able to remove the piece that will end up being the cover for this cavity. Now I need to get the first phase of the cavity space machined out. Right: First cavity machining cut complete. Got the Roland circuit board set in place with (I think) enough room for all the related wiring that comes from it. |

First op in the cavity done. Have a couple other cuts to do to finish this one.

|

|

Making the best possible decisions as we go here - it's all new territory and this bass requires a great deal of planning as we are very limited on space.

|

Left: OK - stop-press change of plan - I decided it was easier in the big picture to machine all the cavity features with the back plate attached so that everything could have a much better chance of alignment. Right: Into the unknown but I think it will all work out. Cutting through the back plate right now which I will remove when done. |

All this came to me while I was supposed to be sleeping last night - it makes more sense to get the cover cut and the cavity below it machined out in one opearion. Might do the other two this way. It will all make sense when I post more progress pictures.

|

|

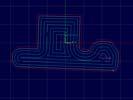

This is a vector drawing of the cavity shape and lid shape. Should leave a thin enough wall at the bottom for the 13 pin assemblies.

|

Left: Small adjustment to shape and size based on cover dimensions. I have to keep the 13 pin assemblies pretty close to the lower edge of the body. This should do the job for the lower controls. Right: This pic is just a shot of my toolpath for the main part of the cavity. I will create other paths for the areas that need to be a little deeper. |

THis shows the toolpath for the main cavity. I will also create paths for the two sections that will be full depth plus lid cutout areas.

|

|

For anyone interested, this area in green is safe to remove material from the back of the body although the pots and 1/4 jack outputs will need to be cut deeper than the other areas!

|

Left: This photo shows the internal area I can afford to cut out to contain the lower controls (outputs and vol/tone pots) plus the Roland circuit board. There will be different depth levels for pots, 13pin and PCB. Right: Just about to run my CNC setup to cut the first cavity. Being as careful as any human can! More updates coming! |

I'm going to run the bottom cavity first. Might need a couple of operations/programs to allow me to customize the specific depths for the various features.

|

|

Will end up with two covers and two cavities of varying depths to house the various controls. I have another toggle switch to place somewhere but at least that will be small! Enough to make my brain explode and I will be glad when I have resolved and cut all of this!

|

Left: The upper bout of the body (as seen from the front) will have Roland program buttons, switch and blend pot in the same group so I should be able to keep cavity lids to only two. Right: I have the body up on CNC doing the 1st cavity, BUT may need to move the Roland program selector buttons to the side due to space constraints. |

As I work though this cavity issue I realized that my only reasonable way to accommodate all the controls is to move the two selector buttons to the upper side of the body. They are very low profile and to me it seems as if anything needs to be on the upper side it should be these two as they would not be seen and would free up some very valuable space!

|

|

I'm trying to determine how deep that first cavity can be to still akkow the 13-pin outputs to sit in place but still leave me enough material relief for access to the tuner knobs. Everything is so tight on this instrument there's no room for error!!

|

Left: The tuners will need a little relief under the knobs to allow access to them, so I have to be extremely cautious about not extending the lower cavity too far into that area. Right: OK I have the two cavities marked out. Took a photo of the areas and I will use that to scale and create the cavities in Illustrator! |

Spent a good chunk of the day on this as there are so many variables to consider. I wantto keep the lids to two if I cando that so I have to consolidate and arrange the electronics fairly accurately where I have space to do so!

|

|

Have the back plate accurately placed on the center line of the existing body. Will cut and sand edges to match and then I can start cutting lid openings etc.

|

Left: I need to trim the back plate to exactly the same profile as the existing body so that I can then cut the plate for the cavity lids. The plate is clamped in the exact central location for me to do that! Right: After some sawing & sanding the back plate is now flush on all sides with the body. This helps greatly in setting cover placement. |

Back plate is now shapes and danded to accurately match existing body shape. I need that accuracy to position the cavity covers..

|

|

Brown areas are existing features (on the front of the instrument) and green are the areas I am working on to refine for cavities. Need to check on retaining screw lengths for tuners. Also will be establishing other areas for circuit board etc.

|

Left: I am drawing up an Illustrator file that places the cavities and covers on the actual existing perimeter of the body. This allows me to generate programs for machining each cavity and related cover. Right: The hardest part of the electronics placement is the area where the 4 output sockets live. Willneed to be careful in this area! |

On the surface of the instrument the placement will look ok, in the cavity it will be very tightly packed. I'm looking for the most compact 1/4in jack sockets available. Those gld knobs are there just for my reference!

|

|

If I can verify all the hardware will fit in their deignated places I will get all the cavities machined accordingly. Stacked pots for Volume and Tone on the magnetic pickups look like they will be ok.

|

Left: The big thing right now is to make sure all the internal components can fit in the areas we want them to be in - I have some stacked pots so making sure these will work on the Vol/Tone positions. Right: Starting with the bottom cavity based on how close I can safely get the components to each other. If I am careful we will be OK! |

Establishing cavity perimeters and writing programs for them. It will be tight but I think we can place everything the way we wanted.

|

|

This is the Graph Tech option for no 9v battery. They also have a PE-0240 system but that is active and would require a 9v battery.

|

Left: I spoke to Graph Tech whose piezo systems I will be using. For a No-Battery solution they suggested a PE-0400 system where the piezos are simply summed and blended with the magnetic pickup output. Right: Objective is to have the piezo signals routed to a 13-pin output on the body. I'm adding that and working on wiring solution! |

I believe that based on the sized of the various internal electronic components this is our bet bet for control layout. I have enough depth now in the body to use stacked pots for Vol/Tone on each pickup. Looks loike Roland stuff will fit in the upper back corner. Biggest components will probably be the two 13-pin assemblies and I am assuming the worst case on this drawing. It's enough data for me to get the cavities programmed!!!!

|

|

Establishing a final carved thumb space allows me to define the available material the set of upper knobs can start. Should not be a problem.

|

Left: When playing the upper frets there needs to be room for the player's thumb. I am cutting that to its maximum extent so that I can define the position of the furthest forward knob location! Right: Looking at the possibility of stacking the Vol/Tone on each pickup and moving those 2 to the more traditional location on the lower bout. |

I'm checking and measuring to see if this could be done. It would be nice to get these controls in a more traditional location if possible. I talked to GraphTech regarding passive Piezo feeds from the bridge units - they told me they should be connected to magnetic output(s) via a special blend pot they make. This would perhaps help in us not needing a second 13-pin output but I will discuss with my customer.

|

|

Audere has three stacked knobs but they have really small potentiometer bases which will allow me to place them on the upper surface of the body. I will have two 13pin and two 1/4in jack outputs. The 13pin circuit boards are bulky so it looks like the best distribution is as ahown above where there will be a jack socket between the two larger units. The two small blak Roland dots are ush buttons for scrolling through MIDI menu items. I'm looking at all the electronic packages right now to get a correct inventory of all the switches and knobs.

|

Left: Looking at all the controls for the instrument so that they can be laid out as close to my customer's preferences as possible. I'm doing an inventory of all the other necessary knobs and switches. Right: We have been updating the control layout options and this is closer to our ultimate goal. Roland controls MAY be able to move. |

We are using passive circuitry for the two magnetic pickups and that allows me to make the top controls a little more discrete on the upper surface which helps me a lot. I'm also going to trt to use the available space to group all the Roland controls together.

|

|

I'm guessing that I will have three cavity covers on the back to provide access to all the electronic components and battery power supply.

|

Left: I now need to make final decisions on the layout of the back access covers top the various components of the electronics in this bass. Not an easy task but one of the last before it goes to finishing!!!! Right: For reference - this photo shows the front and back of the bass. The whole thing will look awesome when the finish is applied. |

IPicture of the front and back of the instrument. The back plate has the same Sapele material alongthe edges and the Wenge part blends perfectly with the taper of the body laminates. The finish will bring out the grain of all these woods and it will look spectacular..

|

|

Marking out the final preimeter of the back plate after which I will rough saw the shape. This will all allow me to get back to the task of chambering out the body for the electronics and wiring.

|

Left: In order to guarantee good alignment with the other instrument features I am clamping the back plate onto the body in order to mark out my cut lines. I will then saw off the extra material. Right: Back plate has been marked and sawn slightly oversize. I need to do some trimming at the neck end to remove some material there. |

I'm working on the back plate now to bring it into size with the body profile. I can now define cavity areas and will use this plate to create blended continuous grain covers - should look very nice.

|

|

Maple veneer attached to both joint edges. Next I will be gluing on the Sapele.

|

Left: Maple veneer has been stuck to the edges of the tapered back panel. Doing some sanding to that and then I will add the additional pieces of sapele! Right: The veneering and assembly gluing of the back panel has been done and I sanded the whole thing on the drum sander to clean up. Looks beautiful and will do its job well! |

The cobination of the woods and the decorative veneer looks awesome and that's before any finish is applied. This panel will do an excellent job to provide fully blended access covers.

|

|

I am machining accurate joint faces onto the sapele side pieces of the back plate.

|

Left: I have the CNC set up to machine the joint faces of the outer pieces of the back plate. Once these edges have been cut I can add veneer and glue the entire back plate together. Right: I am gluing some decorative veneer onto the two outer edges of the wenge panel. This will reflect the other veneers I have used elsewhere on the bass. |

Gluing maple veneer to the two side joint faces of the wenge back plate. When that's done I will glue the two outer pieces on and sand everything nice and level.

|

|

Cutting the ptapered shape of the Wenge to match existing geometry on the back of the bass.

|

Left: Machining the taper of the central piece of Wenge I will use for back plate and cavity covers. When this is done I will glue on the sapele pieces to make one complete assembly. Right: The center piece has been cut and I will now be adding the two Sapele sides (and most likely some decorative veneer) to complete the assembly. |

Tapered center piece has been cut and I will go ahead and assemble the Sapele sides..

|

|

I will be doing a couple of machining operations to this piece of Wenge and ultimately adding the two Sapele side pieces.

|

Left: Setting up the central piece of African Wenge for the back plate assembly. I'm going to machine the thickness of the plate dwn tpo about 5/16 inch thick and then I will machine the tapered profile. Right: Machining this nice piece of wenge down to match the thickness of the sepala pieces I will be adding to the sides. |

Machining down the Wenge to metch the thickness of the sapele.

|

|

I have some Sapele left over from the top plate material and I am planning to combine that with some wenge to create a very fitting artistic back for the body inside of which I can creat all the required contuinuous grain covers!.

|

Left: Looking at some cool woods I have in stock re. the back plate. This would be an elegant solution to the cavity/cavity lids dilemma AND allow me maybe 1/4" more cavity depth to play with! Right: I am now measuring the areas on the bacl so that I can cut and machine the sapele and wenge to create a geometrically matching back. |

These two woods should combine to do a beautiful and artistic back plate which will also incorporate continuous grain covers!

|

|

I'm busy quantifying how many pots and switches will actually be needed to make this thing work. What is shown in a minimum configuration. Also actual locations not yet finalized. A is Audere, R is Roland.

|

Left: I have selected a few areas where I am going to cut initial cavities for electronics and wiring. I will be moving forward carefully establishing these in the body. This illustration shows most of the required controls. Right: I am looking at possibly adding a fairly thin decorative back plate so that I can create matching wood cavity covers. |

The back plate would be a huge help to placing internal components and will allow the addition of beautiful decorative continuous grain covers.

|

|

I have 4 outputs to configure in the lower right area of the body- working on that right now to make sure I have space for all of that hardware!!.

|

Left: My big goal here is to get the rest of the cavities machined so that I can get this instrument off to finishing. It will come back looking awesome and I will then be able to dig into all the electronics. Right: I can create cavities for most of the electronics that need to be in this body & calculating whether the body thickness is adequate. |

I do have space under the pickup area to create some space for electronics although I don't want to weaken the structure that has to hold up to the string tension. I'm wondering if it would be wise to create a back plate which would then allow me to create as many lid/covers as needed while helping add a little thickness to retain core strength. I love the laminates on the back but if I cut cavities in that I can't make matching lids. I may have some really nice material I can use that would look just as good. Lots of stuff in a very small space.

|

|

I think I got the recesses deep enough to work on the finished assembly. There are 8 wires that now need to have some clearance machined so they can pass through to the control cavity area.

|

Left: Bobbin relief in the body has been machined. I need to now do some test fitting to set the best area to allow the wiring to be channels through to the area where the controls will be. Right: Working on the wiring channels under the top plate so that the pickup and other necessary wiring can run to the correct places! |

I will be running 4 pairs of wires from the magnetic pickups, a wiring cable from the Roland pickup, six piezo wires and eight grounding wires from the bridge units. I have to account for everything that needs clearance or channels under the top plate.

|

|

I was right in the middle of cutting the pickup recesses when the old computer failed. Got hold of a replacement and busy setting it up and installing the software. Like I had nothing else to do today!

|

Left: I'm in the process of upgrading my CNC computer today - the old one decided it was not going to all the work for such low pay and it quit on me yesterday! Right: Now machining the relief for the pickup bobbins under the ramp area. I will need to do a calculation to decide how deep to go with these recesses but so far so good. |

Machining pickup relief into the instrument body.

|

|

Once this relief pattern has been cut out of the body material I will be able to test fit the ramp/pickup assembly and make sure everything lines up and fits.

|

Left: I did some CNC programming so that I can cut out the relief for the lower half of the pickup assemblies below the ramp. I'll get this on the machine and get it all cut out asap. Right: The instrument is now up on the CNC and I will be cutting out relief for the lower parts of the pickups as they are laid out under the ramp we created. |

Getting ready to cut pickup recesses!.

|

|

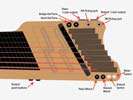

This photo shows what the pickup ramp is planned to look like after all this hardware is installed..

|

Left: This picture illustrates a little better what the ramp will end up looking like when fitted into its recess on top of the body. Right: I have been creating a layout that allows me to place the output sockets in the required locations and also house the Roland and RMC electronics plus the various pots, battery locations etc. Crazy! |

IWhen I cut the recesses for the pickups in the ramp piece I made sure to keep the wood about the top surfaces of the pickups quite thin (around .050"). This allows the internal pickups themselves to be adjusted upwards as close to the strings as possible. There will be adjustment screws and springs etc to make the ramp behave just like one oversized pickup.

|

|

I will be machining clearance below the ramp for the bottom of the pickup array to provide the right height and adjustment range. I will also machine wiring channels before the top gets glued on.

|

Left: With a clear picture of the placement of the 4 pickup bobbins I am now modifying the locations for all the remaining internal bits and pieces so that I can cut cavities in which to house them all! Right: A slightly simplistic illustration showing a side view of body and the ramp/pickup assembly's relationship to body/strings. |

IWhen I cut the recesses for the pickups in the ramp piece I made sure to keep the wood about the top surfaces of the pickups quite thin (around .050"). This allows the internal pickups themselves to be adjusted upwards as close to the strings as possible. There will be adjustment screws and springs etc to make the ramp behave just like one oversized pickup.

|

|

I could probably also use hot glue to make sure these pickup bobbins are very solid. Have a few options. This is ALL unknown territory so we will see what's needed as we assemble the ramp.

|

Left: This photo shows the first of the four pickup bobbins fitted into the correct recess. Nice and snug and I will be adding small screws to make sure these bobbins are held securely. Right: I fit all 4 bobbins into the ramp and I am now looking at the possiblity of attaching the top plate to the body. Some wiring channels to cut first though. |

This photo is a testimony to accurate machining. The four bobbins fit in there just the way I wanted them to!

|

|

I just programmed the locations for the four pickup bobbins! Ready to do the machining..

|

Left: I am getting ready to machine out the recesses on the back of the ramp plate. Goal is to leave about .050 to.060 inches of material at the bottom of each of the recesses. Right: I'm working carefully on the back of the ramp to establish the four pickup biobbin recesses. Tricky job with very tight tolerances!! |

INot mucg room for error on the back of this plate! Wish me luck!.

|

|

MDF ia a great material for incidental fixtures like this that I will only use one time. It will guarantee correct placement of the machined features.

|

Left: This nice chunk of 1" MDF is going to be my fixture for the remp machining. I have a drawing and a program already made for this so I'm getting ready to set up and do the machining! Right: The cutting of the fixture is under way. I'll use this to accurately locate the underside of the ram for the machining of the pickup recesses. |

Cutting the holding fixture on the CNC.

|

|

First job is to cut recesses in the back of the ramp to locate the pickups and place them as close to the strings as possible.

|

Left: Next challenge is the placement and machining of the four recesses for the pickup bobbins. I'm starting in a vector program and creating a CNC program from that. May need to make a fixture. Right: I am creating a recessed fixture so that I can safely hold the ramp piece while the pickup cavities are being machined. |

I wanted to see the actual pickups on the back of the plate - will keep them near the machine to make sure everything fits!.

|

|

This operation will separate the ramp material from the rest of the top plate.

|

Left: I set up and machined a fixture that would hold and position the top plate in the correct location and I am now machining the ramp perimeter from the back side of the top plate. Right: Finally - ramp plate removed from top plate - everything went well and now I can work on creating recesses in both body and ramp for the 4 pickups!!! |

Made it this far. Next I will be machining the back of the ramp in order to fit the 4 pickup bobbins in place.

|

|

I have to make these cuts in several passes to avoid the little carbide cutter breaking.

|

Left: Making the commitment to machining out the ramp. I am using a very small cutter to minimize the material removed and optimize the fit when we're done. Going very carefully. Right: So far so good - this pickup area is very carefully designed to keep the 4 pickups as far apart as possible for optimum performance. |

IThis is the first cut - about 1/4 inch deep.I need to reset the top plate on the CNC and machine from the back to release it completely. Then I will machine the ramp to house the 4 pickups.

|

|

This profile is a result of aLOT of measurement and calculation related to all the features that need to exist between the bridges and the neck.

|

Left: After the recent adjustments this is the final path for the ramp which I have now programmed. I'll get this cut and probably make a template for further machining. Right: I have the top set up on the CNC to cut the ramp profile. I have a print of the ramp to scale positioned exactly where it has to be to facilitate setup positioning. |

I will use a very small .031" cutter to machine as deep as I can round the ramp. I'll need to flip it over and machine from the back to release it.

|

|

Setting yup to clean up and square off a couple of fairly important reference surfaces.

|

Left: On another area of my CNC table I am setting up the body in order to clean up a couple of surfaces at the end of the neck. Need to have everything fit just right with no room for error!!! Right: This is the first of a few machining operations on the top plate. Right now I am cleaning up the neck joint angle for positioning. Next will cut ramp. |

Since I need a greater than usual degree of accuracy on these features I'm making sure top/neck joint is accurately set before positioning and cutting ramp area.

|

|

This appears to be the best compromise for the ramp shape. Next move is programming and cutting it out of the top plate.

|

Left: This is the area (white) that all these measurements and calculations has yielded for the extent of the pickup ramp. It leaves space for Roland pickup and a little finger space for slapping. Right: I have written a program that will allow me to harvest the ramp plate from the top plate of the instrument. Just need to position it and get it cut. |

Working on the CNC setup where I will be cutting the ramp plate out of the top plate.

|

|

I'm checking with Mark to see whatthe absolute minimum distance can be between the two sets of pickups. I could always create more space by shortening the fingerboard by 1 fret but I would much rather not do that!.

|

Left: That blue tape against the fingerboard is about one inch wide. I'm hoping that will provide enough finger space for slap-style playing since the pickups need to be separate enough not to affect each other. Right: I have established limits for the ramp and looks like I can go ahead and get that ramp shape cut out from the top plate. |

Doing some actual measurements while duplicating the correctly sized components on the computer. Difficult job.

|

|

While I am working on all the top features I might as well add this little nameplate to the list!.

|

Left: Very little space on this instrument to add the brand name and serial so I may place it on a recessed section just behind fret 30. It wont get in the way of finger space as it will be almost flush with top surface. Right: Here are the parts in place showing us what we can get away with space-wise. It's close but I will do my best!!!! |

On the right side we have the tunets whose positions are pretty much fixed based on scale length requirements. On the left we want to leave a little finger space for slapping style playing. In between those two points we have a Roland pickup, the side walls of the ramp (which can be pretty thin) and two pairs of pickups which can't be too close to each other because of phase/polarity issues.

|

|

The top plate will have the ramp section machined out and that piece will have some machining done on the underside. I'll also have corresponding recesses machined for the pickups in the body below the ramp. I have to be very careful about placement!.

|

Left: I'm going to be working on this top plate to get the ramp cut out and machined. Doing some measuring and programming right now so that I get everything in the right place! Right: I cut the pickup shapes out on the laser (easier and safer than using actual pickups) so that I could verify placement and alignment of each. |

These replicas of the individual pickups will help me verify a few things related to the shape and size of the ramp.

|

|

Got the second pickup array from Mark and I now have what should be a great source for the magnetic pickup signal on the bass.

|

Left: I got the set of new pickups from Mark. This is about as custom a set of pickups as I have seen but glad we got through all the work and I have these on hand now. Right: Now that I have the actual pickups I can finalize the ramp preimeter and get that marked, programmed and cut out! Should be exciting to see all this happen! |

These are the new pickup units placed in the body and the resulting ramp perimeter drawn around them. I will be using this geometry to get the blank cut for the ramp area.

|

|

Heard from Mark that these bobbins have exactly the desired output levels and based on their copper gages and windings are well balanced. He need to add wiring and get then potted after which I will find a way to get back over there and pick these up!.

|

Left: Pickups have been wound with nice even output and so far this revision of them is giving us good output measurements. They are about to be finished up and potted. Right: The four pickups have now had their terminals installed and output wires connected, then taped, insulated and potted and re-tested. |

Mark has been amazing in this very difficult process of creating custom pickups for me. Looks like we finally have a set that will work in this unusual bass.

|

|

These are the redesigned pickups in the process of being assembled. Bottom bobbins allow me a means to attach the bobbins to the ramp plate.

|

Left: These are the bobbins with the revised engineering in order to give me a way to fix them to a ramp plate from underneath. Lots of inventing going on here to achieve desired results. Right: Winding on the recently revised bobbins has been done. I'm waiting to hear from Mark how their output properties measure up. |

My feedback from Mark on this batch is good so far - he is winding in such a way as to make sure the output from each set is suitably balanced. He has out a lot of work into this!!!.

|

|

OK - this pic shows the ramp area plus the pickup placement and spacing. I need to devise a way to lock the pickup bobbins into the ramp so that they are fixed firmly to the top surface. It's a complicated job..

|

Left: Back to the pickup ramp work - firstly I will be cutting out the ramp piece based on the pickup and Roland unit placement. After that I need to machine recesses in ramp and into body. Right: OK - after consultig with Mark I adjusted a few things so that the bobbins and the ramp will lock together better. This is all very complex work. |

I'm adding a clamping system to the bobbins to facilitate the locking of the pickups to the underside of the ramp. We're breaking a lot of new ground here and adjusting as we go and learn.

|

|

Bobbins are complete! I now need to get them to my winder who is a couple of hours away.

|

Left: I have all the magnets installed in the pickup bobbins and now I have to get them to my electronics guru for winding. Will be heading there soon. Right: I had a chance to drive to my electronics guy in La Quinta so I brought the pickup bobbin assemblies to him so that he could work all his magic to them. Looking forward to getting that done. |

He's not real close but it's wirth the drive. I go through the mountains on smaller roads as it;s quicker than dealing with the freeway traffic!.

|

|

We had flipped the layout of the bass pickups but, as a result of exploring this from an electronics point of view, it will cause out of phase issues and I have been strongly advised to stagger them as shown for best results!.

|

Left: A feature we were hoping to include turns out not to be advisable. I had to revert to the P-Bass pickup layout because the "flipped" layout I illustrated earlier will cause phase issues. Right: I am assembling the for pickup bobbins with their magnets so that I will have a full set to take to my winding subcontractor. Getting there! |

In the middle of assembling the pickup bobbins and magnets!.

|

|

Assembling the four pickup bobbins.

|

Left: Collecting all the magnets and other tooling so that I can assemble the four pickup bobbins.Once they are assembled I will have them copper wound and potted. Right: I have a scaled drawing of the layout area for the pickups. I'll create this from the parent material of the top plate of the body. Should work & look fine! |

I roughly laid the bobbins out to see how they looked on the top of the bass.

|

|

I roughly laid the bobbins out to see how they looked on the top of the bass.

|

Left: Just wanted to roughly show the pickups as they will be laid out on the top of the instrument. Should all work out fine. I just wanted to see how they looked in place so though I would share! Right: Working on the geometry of a ramp area under which these pickups will eventually live. Calls for some creative machinery :-) |

II may modify this geometry slightly but basically it will be a plate under which all four magnetic pickups will live.

|

|

Each pickup is unique in terms of string spacing so I have to make sure they are labeled for the laser!

|

Left: This is what all 4 magnetic pickups look like. They are colored just because I don't want to get the pole spacing mixed up. I'll be creating these on the laser. Right: I cut all the required bobbins for the two sets of magnetic pickups based on last engineering changes. Good to have these and I will be assembling them with their 32 magnets! |

Cut the bobbins on the laser and they are now ready for assembly!!

|

|

Slight re-design of the bobbins so that I can keep them as compact as possible. It would be nice to just buy commercial pickups for this but because of the pickup angles, the small body and the need to save space plus the desired sound characteristics, there is no way I could purchase something like this. I am lucky I have a laser and I can custom create objects like this!!

|

Left: In order to keep bobbin/pickup size compact I re-designed the placement for the adjustment screws so that I only need three screws for each. This shoudl help a lot! Right: OK - this is the result of the recent engineering mods - I think it will work really well so I am going to go ahead and cut the whole set and keep moving! |

I cut the new bobbin design and it seems that it should work fine. I'll be testing it in custom covers soon too. Should look and sound good!

|

|

TThe magnetic pickups will need height adjustment so I am looking for the smallest screws I can find that will do the job so that I can keep the pickup sizes assmall as possible since we want a lille slapping finger space near the fingerboard.

|

Left: I am now getting ready to cut bobbins for these pickups on the laser. After cutting I'll assemble with magnets and have them copper wound. Also looking at the best way to add height adjustment screws on the covers. Right: Test cutting pickup bobbin to evaluate several things. Want to keep these as compact as possible. |

I cut a pickup bobbin to see if it's compact enough to work on the bass, but big enough to take enough copper winding. Also need space for the little wire terminals. This will tell me a lot and help me build these with confidence as they need to be fairly custom assemblies.

|

|

These bobbins and pole spacing are a product of my calculations. Now I have to manufacture the bobbins and collect 32 magnets.

|

Left: Based on my recent calculations these are the 4 pickup bobbins we will be creating. I'm leaving enough room on them for plenty of copper wire so that they are nice and hot!. Right: I happened to bring the bass from my shop inside to my clean room workbench and noticed that the side dots were glowing! Thought I would take a photo. |

The side dots got some daylight from my workshop and I noticed them glowing when I brought the bass indoors.

|

|

The placement and string spacing of the poles are important factors in laying out the phyical design and sizes for these pickup bobbins. I need to also leave enough space so that we have room for the best copper wire type/gage and number of windings. I will be cutting these soon on the laser.

|

Left: Now that I have a plan for pickups and electronics I can work on the string spacing and physical design of the two sets of pickups so that I can cut the bobbins and get these wound. Right: I calculated string spacing based on string gages and from there I was able to place the pickup pole placement at the required pickup angles! |

All these calculations end up giving me the correct spacing for the poles on the pickup bobbins.

|

|

Mark was kind enough to send me some thoughts on how we might deliver all these different sound sources through the 4 outputs on the instrument. More on this coming.

|

Left: I heard from my electronics guy that the overlapping pickups will yield different output volumes and will present problems - much safer to go with full 8-string pickups or pairs of 4. Right: Now that we have a better concept of how the magnetic pickups might be configured I have to look at the wiring challenges that will be involved. |

It helps to know the magnetic pickup plan. Now I have to look at the challenge of how all these sound sources can be connected together and how the physical electronic components are inter-connected so that they can be built into the existing body of the instrument. I'm making a diagram of hardware for Mark so that we can study all of this.

|

|

We might do a reverse arrangement on the neck pickup setup. Also decided we could add a small extension to the Roland pickup to balance the visual appearance.

|

Left: My customer asked me if we could stagger the bobbins on the neck pickups to maybe gain a little tonal advantage. I'm not seeing a problem with that. Right: My customer asked me if I can possibly extend the split pickups to six poles/strings each. Working with my electronics guru to see if that's something we could incorporate. |

I don't know if we can do this yet but waiting to find out.

|

|

Just another option for the magnetic pickup layout so that we can provide the best and most diverse sound without phase issues or compromising body strength against approximately 600 lbs of total tension from the strings!.

|

Left: I also have access to commercially available 4-string BLADE pickups. These could be arranged as shown in the photo. Any of the 4 configurations below is possible based on my interaction with Mark. Right: Because this is such a complex project electronically, Mark and I decided to test wind an 8-string pickup bobbin and see how it works out. |

Just another option for the magnetic pickup layout so that we can provide the best and most diverse sound without phase issues or compromising body strength against approximately 600 lbs of total tension from the strings!.

|

|

This image shows the combination of a single and a split pickup combination.

|

Left: Another option for us is to have one straight 8-string bobbin and have the neck pickup be designed a little like a P-Bass split pickup using two 4 string bobbins. Right: And a third option would be to split both pickups.Makes winding easier but the combination does occupy more space. Still leaving room for a little slapping space at neck. |

In this picture it shows two sets of split pickups.

|

|

I am machining a wiring exit slot in six of the AMB tuners for the piezo wires.

|

Left: I am in the final round with Mark looking at what options he can provide me for the best tonal output for this bass monster. We have narrowed down a few things. Right: After exhaustive discussions about pickups in this 3" space, for the sake of the best sound from this bass Mark and I are strongly suggesting fixed separate pickups. |

According to Mark we CAN wind copper on an 8-string bobbin so we do have a choice of creating two pickups similar in shape to J-Bass style. Doing this also avoids the possible structural cross section weakness of the sliding pickup recess that I was concerned about under the tension of 8 bass strings.

|

|

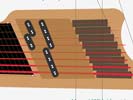

The blue area is the body shaope as it is right now. Brown area is the anticipated slightly shortened body shape. Green is the area of the revised body shape that is recessed for finger access to the knobs. For anyone looking at the bass the green area would appear as part of the body.

|

Left: I hope this photo makes sense. I am showing three areas. Original body shape, reduced body shape and recess area on reduced body shape below tuner knobs. Right: Six of the tuner units have to have special piezo saddles installed and to aloow for this I have to machine a slot in the bottom of each unit for the signal wire. |

I am machining a wiring exit slot in six of the AMB tuners for the piezo wires.

|

|

This would work great from a manufactureing perspective but required too much linear space. I asked about reducing the same system to a 4 pickup layout to see if it would fit in the 3" or so that we have to work with. It might but he pointed out that if that were the case we'd be better off with the tonal diversity of two separate 8 string pickups.

|

Left: Mark had a concept for a pickup array housed inside the elongated cavity but we discovered that it would need to be about 6" in length to avoid magnetic field issues. Right: Something that occurred to me in all this intensive pickup conversations - I have a very narrow body with 8 strings of combined tension. Looking at the physics... |

The geometry of this bass with its narrow body and the combined tension of eight strings brings up a few questions about inherent strength IF we machine out a big cavity for sliding pickups. Most of the 8 string tension will be transferred to the area of the body below the pickup recess.

|

|

Mark and I are in regular communication to find the best way to produce a detectable difference in tone using the 3" wide space on the instrument. Given that a pickup has to have a magnet large enough to overcome the difference in string spacing, a copper coil with a minimum of 1/8 buildup and bobbin to provide spacing an clearance, the distance a pickup can move within that 3" space would be around 2.25" Based on the flux of a vibrating string that distance of travel yields a fairly subtle difference in tone. Mark has a concept he is working on of his own design to overcome this and the inevitable phase/signal challenges.

|

Left: Main restriction in using a pair of sliding pickups is that no matter how they are designed there will be a phase issue when they are close to each other causing an imbalance in output. Right: I sent drawings to my electronics guy to seek some more information on the different options we might be able to employ.. |

I sent these pics to Mark with a list of questions so that I could better understand his concerns. I will be updating this page as I learn and develop solutions with him.

|

|

The tuners have to be in fixed positions based on relative scale lengths but that still leaves some material that can be removed from the very back of the bass. The objective is to do that while retaining the curved feature. Roland pickup can't be more than 50mm from bridge locations. I have to bear in mind that the lower strings will have a lot more backward intonation adjustment but as long as the pickup is parallel and close to the tuners it will remain within that range.

|

Left: While Mark is pondering over pickup criteria I have been finalizing locations of tuners and Roland pickup on the body. I will be trimmimg off a little from the back of the body contour. Right: In my ongoing dialog with Mark, he is suggesting that we could maybe make it work with two bar magnets (4-string each) under special conditions.. |

We are thinking that if we have two bar magnet pickups (somewhat similar to above) moving independently this would hopefully defeat loss of volume and tone as the string separating varies from front to back of travel. Mark indicated that tp avoid out of phase issues they would need to act as single coil when separated and humbucking when aligned together.

|

|

May be able to reduce the length of the body slightly once I have done some calculations based on positioning of tuner units.

|

Left: Checking now using ABM tuners to establish how much material I can safely remove from the back end of the body. Lot of calculations involved based on scale length and intonation adjustments. Right: I have been having regular emails with my electronics expert to discuss the details of how to achieve the sliding split pickup. |

Mark is working on finding a way if possible to avoid two 4-pole pickups causing phase interference with each other. They also need to track the natural taper in the strings.

|

|

The tuners actually cost more that the finishing process. ABM have been very busy over in Germany as they are the only ones with a proven ptroduct like this.

|

Left: I ordered eight of these tuners and recently checked with the supplier. They were fairly sure they would be able to get them for me in time for the post-finishing phase of this bass. Not cheap but best option on the market. Right: Very happy to announce that my set of 8 ABM tuners has arrived safe and sound. Thank you ABM! |

Well. I don't have to worry about these any more. I had heard that they are hard to get and ABM have been saying repeatedly that they are out of stock and it would be some considerable time before they ware available again!.

|

|

The green area on the photo shows the area occupied by the tuners. We may slightly modify the end shape of the body.

|

Left: I anticipated that the Roland pickup would be fixed at its Roland recommended distance from the bridge units. I'm calculating the sliding pickup recess based on that and some finger space at the end of neck! Right: With Mark's help I am better able to visualize how these two sliding pickups might interact. Tricky but do-able I think. |

Two 4-string groups of individual puckup modules which will be compact enough to pass by each other. More info on all of this coming soon..

|

|

The green area on the photo shows the area occupied by the tuners. We may slightly modify the end shape of the body.

|

Left: We are taking a quick look at the back of he body and its size/shape relationship with the tuner array. We may remove a little more material to bring the backshape inward slightly. Green is tuners, yellow is the pickup recess area. Right: It looks like I can shorten the back of the body a little which I will do after I fit electronics. |

I hope this image can illustrate the difference - based oin tuner locations I can take off a little bit at the end of the body.

|

|

Working on a very unique pickup design. Best scenario is an 8string split pickup that allows two separat 4-string sections to travel forwards and backwards. Some electrical engineering involved!

|

Left: I have been discussing the split pickup scenario with my pickup expert and we are developing something that might work. We're looking at all the technical stuff right now. Right: The pickup dimensions and poles may be able to be altered to make the pickups a little taller. We think this will reduce or eliminate the overlap. |

Tentative design on special pickups for this bass. We are currently working on actual string spacing to verify that the laws of physics will allow us to do this.

|

|

Not the cheapest or technically easiest solution since it requires the winding of four smaller pickups but it seems to be the closest formula to the goal.

|

Left: I have given this whole thing a lot of thought. In my opinion the best way to achieve the sliding pickup solution is to have two narrow 8-string pickup assemblies using ploes or blades (blades perhaps better) and allow these to travel together or separately to produce pretty much any tone combination. Two half pickups can't really cross oe overlap each other's path because of the necessary conflict of individual coil windings. |

|

I have to cut out a piece of the top plate and use that piece as the bottom of the pickup recess. To do that I am carefully establishing the maximum area the pickup parts can live in.

|

Left: Establishing the area I will be machining for recess in which the pickup components will travel. This is based on scale length and the physical sizes of the bridge/tuner units I will be using. Right: While I am planning out all the recesses needed in the revised body I am also working on the best way to design a split pickup geometry. |

Because of the necessary overlap of copper winding it's not easy to creat e a split pickup where the travel on each half is able to overlap the other. Working on a few ideas - will update.

|

|

IBody is much more compact now. Next I have to look at the pickup recess based on maximum travel and how that split pickup is going to separate.

|

Left: I have carefully machined the upper and lower body edges to a finished condition. This in turn helps me get more material removed around neck both at body and headstock. Right: I'm working on the final shaping of the headstock. I'm removing material to a minimum condition with the fit and function of string retainer in mind. |

Body is much more compact now. Next I have to look at the pickup recess based on maximum travel and how that split pickup is going to separate.

|

|

Machining the outer (straight) edges so that we have finished surfaces on the top and bottom surfaces of the body.

|

Left: Setting up to do some trimming along the top and bottom edges for the body to finish that up. I will also be working on the other features around the perimeter. Right: On the CNC so that I can establich a clean finished edge on upper and lower body edges! Bass a little bit lighter thank to removal of extra material. |

I was able to do it this way thanks to having a milling cutter with long flutes.

|

|

Body is now trimmed in line with the angles of the sides of the neck.

|

Left: I went ahead and trimmed the body to make it slimmer per my customer's preferences. I will plan recesses in the resulting body shape to house the various electronic parts! Right: Setting up the CNC tp add threaded holes to the string retainer so that I can install set screws which will give us the string clamping capability. |

Had to make anothere custom fixture to allow me to accurately place the threaded holes for string clamping!.

|

|

Retainer is drilled and fitted. Needs clamping and retaining screws but I can shape the remaining headstock material to reduce to the finished size and shape.

|